Vitamin A (C20H30O) is a fat-soluble nutrient which naturally occurs in various foods. It is a vital nutrient which is a vital part of the healthy functioning of many organs as well as the immune system, the retina, target tissue growth and differentiation, and reproductive organ health.

Request for Real-Time Vitamin A Prices: https://procurementresource.com/resource-center/vitamin-a-price-trends/pricerequest

It is made using a chemical synthesis from petroleum-derived substrates like acetone and acetylene. Its respective melting and boiling points are 62–64 °C (144–147 °F) and 137–138 °C (279–280 °F).

Key Details About the Vitamin A Price Trend:

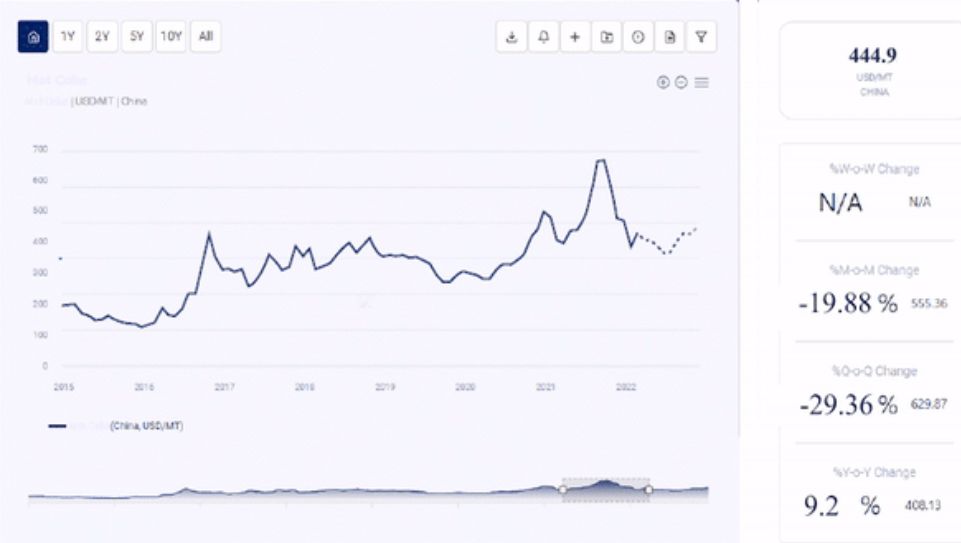

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Vitamin A price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The Vitamin A Price forecast, including India Vitamin A price, USA Vitamin A price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Vitamin A Price Trend:

Vitamin A is a crucial nutrient found in foods and beverages and plays a key role in improving nutrition and overall health, which is the main factor driving the industry’s growth. Furthermore, the growing demand for functional foods and dietary supplements among health-conscious consumers is boosting the market growth further. In the beauty industry, vitamin A is used to improve the look and health of skin and hair, which will further the industrial demand. Also, the growing R&D initiatives taken by the government, along with the expansions and product developments by key players, will boost sales in the sector.

Key Players:

- BASF SE

- Penta Manufacturing Company

- Acros Organics

- Cipla

- Phizer Inc

- Amway Corporation

- GlaxoSmithKline plc.

News & Recent Development

- 26 April 2023- The drop in prices of Kingdomway’s vitamin A coenzyme was attributed to frail demand and oversupply of vitamin A and coenzyme Q10, which caused a decline in both the raw material’s prices.

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA