In an era where the energy sector’s dynamics are constantly evolving, understanding the intricacies of natural gas production and its associated costs has become paramount for stakeholders across the globe. The latest report from Procurement Resource meticulously unpacks these complexities through an extensive analysis of natural gas production cost processes, offering invaluable insights that could revolutionize strategic decision-making in the industry.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/natural-gas/request-sample

Procurement Resource Assessment of Natural Gas Production Process

Procurement Resource, a leading firm specializing in procurement research, has released a new report that dives deep into the natural gas production process. This detailed assessment aims to provide stakeholders with a clear view of the operational structure, economic factors, and technological requirements involved in natural gas extraction and processing.

Natural gas, primarily composed of methane, is a critical source of energy that supports residential, commercial, and industrial activities worldwide. The production of natural gas involves several stages, including exploration, drilling, extraction, and processing, each associated with specific costs and technical nuances.

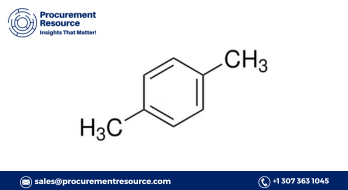

Product Definition

Natural gas is a fossil fuel used mainly for heating, electricity generation, and as a feedstock in the manufacture of various chemical products. Unlike other hydrocarbons, natural gas is cleaner-burning and emits lower levels of harmful pollutants, making it a preferred choice amidst growing environmental concerns.

Market Drivers

The demand for natural gas is driven by its role as an energy source with lower CO2 emissions compared to coal and oil. The shift towards sustainable energy practices, coupled with the expansion of the industrial sector and increased residential energy needs, particularly in emerging economies, has significantly propelled the market forward. Additionally, advancements in extraction and processing technologies have made it more feasible to tap into previously inaccessible or uneconomical gas reserves.

Raw Materials Requirements

The extraction of natural gas requires substantial investment in both equipment and technology. Key raw materials include drilling fluids, steel for pipelines and drilling rigs, and chemicals used in hydraulic fracturing. The availability and cost of these materials directly influence the overall production expenses.

Costs and Key Process Information

The report from Procurement Resource breaks down the cost structure of natural gas production, highlighting key expenses involved in each stage of the process. Initial exploration costs are significant, involving geological surveys and the use of sophisticated sensing equipment to locate viable gas reserves. Drilling, one of the most capital-intensive phases, requires advanced machinery and skilled labor. The extraction phase often involves hydraulic fracturing or “fracking,” which necessitates a considerable amount of chemicals and water.

Post-extraction, the gas must be processed to remove impurities and byproducts such as water vapor, carbon dioxide, hydrogen sulfide, and sometimes helium. This stage is crucial as it ensures the natural gas meets market specifications and safety standards for transport and use.

Looking for an Exhaustive and Personalized Report That Could Significantly Substantiate Your Business?

Recognizing the diverse needs of its clientele, Procurement Resource offers customized reports tailored to the specific requirements of businesses. These reports are crafted to provide a detailed analysis of the production costs, supply chain metrics, logistical challenges, and economic considerations pertinent to the client’s focus area within the natural gas sector.

These personalized reports are designed not only to offer a snapshot of the current market landscape but also to forecast future trends, potential market disruptions, and emerging opportunities. This enables businesses to strategically position themselves for both short-term gains and long-term growth.

Conclusion

As the global energy sector continues to evolve, the demand for detailed and actionable insights into natural gas production cost becomes even more critical. The comprehensive report provided by Procurement Resource furnishes industry stakeholders with the knowledge needed to navigate this dynamic market effectively. With its in-depth analysis and customized options, this report is an indispensable tool for anyone looking to enhance their strategic planning and optimize their operational capabilities in the natural gas industry.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA