The latest report titled “Propyl Gallate Production Cost Process” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Propyl Gallate.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Propyl Gallate production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Propyl gallate is a synthetic antioxidant commonly used in the food, cosmetic, and pharmaceutical industries to prevent oxidation and extend the shelf life of products. Understanding the production cost process of propyl gallate is essential for manufacturers to ensure profitability, competitiveness, and product quality. This article aims to explore the intricacies of the propyl gallate production cost process, examining the underlying factors, recent trends, and strategies for cost optimization.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/propyl-gallate/request-sample

Overview of Propyl Gallate Production:

Propyl gallate is typically synthesized through a series of chemical reactions involving the esterification of gallic acid with propanol. The production process involves several key stages:

- Raw Material Preparation: The primary raw materials for propyl gallate production include gallic acid and propanol. Gallic acid is commercially available or can be synthesized from tannins found in plants. Propanol, typically in the form of isopropanol or n-propanol, is sourced from petrochemical or renewable sources.

- Esterification Reaction: Gallic acid and propanol are reacted in the presence of an acid catalyst, such as sulfuric acid or p-toluenesulfonic acid, to form propyl gallate and water. The reaction is typically carried out under controlled temperature and pressure conditions to optimize yield and selectivity.

- Neutralization and Purification: The crude propyl gallate product is neutralized to remove excess acid catalyst and other impurities. Neutralization may involve washing the product with water or dilute alkaline solutions. The purified propyl gallate is then filtered or centrifuged to remove solid impurities.

- Crystallization and Drying: The purified propyl gallate is crystallized from solution by cooling or evaporation. The resulting crystals are washed with a solvent to remove residual impurities and then dried to remove moisture, yielding pure propyl gallate powder.

- Formulation and Packaging: The dried propyl gallate powder is formulated into the desired grades suitable for various applications, such as food additives, cosmetic ingredients, or pharmaceutical excipients. It is then packaged in bulk containers or smaller packages for distribution and sale.

Factors Influencing Propyl Gallate Production Cost Process:

Several factors influence the production cost process of propyl gallate:

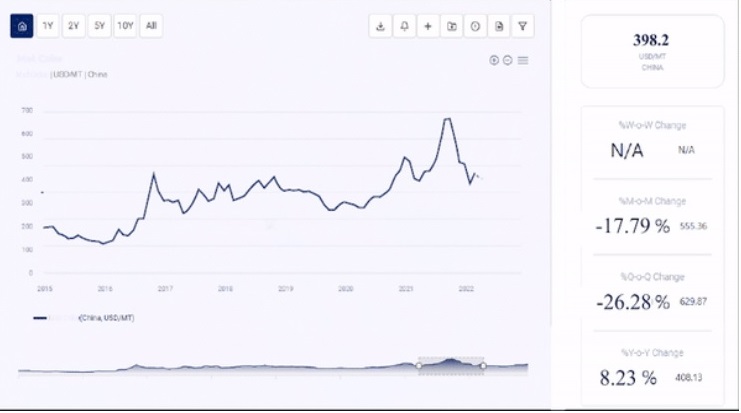

- Raw Material Costs: The prices of raw materials such as gallic acid and propanol directly impact production costs. Fluctuations in raw material prices, influenced by market demand, supply availability, and geopolitical factors, can affect overall production expenses.

- Chemical Reaction Efficiency: The efficiency of the esterification reaction and subsequent purification processes affects production yields and resource utilization. Optimizing reaction conditions, catalyst usage, and process parameters can improve efficiency and reduce production costs.

- Energy Consumption: The production process involves energy-intensive operations such as heating, mixing, and drying. Energy costs, including electricity, steam, and fuel, significantly contribute to production expenses and are subject to market fluctuations.

- Labor Costs: Skilled labor is required for operating production equipment, monitoring processes, and performing quality control tests. Labor costs, including wages, benefits, and training expenses, constitute a significant portion of production costs.

- Equipment and Facility Costs: Capital investments in production equipment, reactors, purification systems, and infrastructure impact production costs. Maintenance, repair, and depreciation expenses also contribute to overall expenses.

Procurement Resource Assessment of Propyl Gallate Production Process:

- From Esterification Reaction: This report presents the detailed production methodology and cost analysis of Propyl Gallate industrial production across Propyl Gallate manufacturing plants. The preparation process starts with the chemical reaction of gallic acid, also known as 3,4,5-trihydroxybenzoic acid, with propanol. This reaction occurs in the presence of lipase as a catalyst, leading to the formation of propyl gallate as the end product.

Product Definition:

Propyl gallate, a chemical antioxidant, has a molecular formula of C10H12O5 and a molecular weight of 212.20 g/mol. It is a white powder with no odor, derived from the esterification of propanol with gallic acid in the presence of a catalyst. The compound has a mildly bitter taste and a melting point between 147-149 °C, decomposing at higher temperatures. Its flash point is approximately 187 °C, and it is soluble in water and various alcohols but slightly soluble in acetone. With a density of 1.21 g/cm3, propyl gallate is denser than water and has a vapor density of 7.3, heavier than air. While stable under normal conditions, it decomposes when heated, emitting acrid smoke. It reacts with oxidizing agents and metals like iron but is incompatible with strong acids, reducing agents, and bases. Propyl gallate is used as a preservative in food, pharmaceuticals, and cosmetics. In food production, it extends shelf life and prevents spoilage in products like vegetable oils, candies, and chewing gums. It is also used in skincare products, cosmetics, and pharmaceuticals for its antioxidant properties, including in the acne treatment Absorica.

Market Drivers:

The demand for propyl gallate is primarily fueled by its role as a preservative and additive in the pharmaceutical, cosmetics, and food industries. Its wide-ranging applications across various sectors drive significant demand. In food processing, propyl gallate is used to extend the shelf life of packaged foods, contributing to its demand in the food industry. Additionally, its inclusion in skincare, personal care products, and certain pharmaceuticals, particularly in acne treatments, boosts its demand in the cosmetics and pharmaceutical sectors. The expanding applications of propyl gallate positively impact its demand, leading to increased utilization in these industries globally.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

- Adapting the report to the country/region where you intend to establish your plant.

- Adjusting the manufacturing capacity of the plant according to your needs

- Customizing machinery suppliers and costs to meet your requirements.

- Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA