In the dynamic landscape of the chemical industry, understanding production costs and processes is imperative for strategic decision-making. Today, we introduce a breakthrough report – the Trimellitic Anhydride Production Cost Analysis Report. This comprehensive study delves into the intricacies of Trimellitic Anhydride production, offering invaluable insights for stakeholders across the industry value chain.

Request for Free Sample: https://www.procurementresource.com/production-cost-report-store/trimellitic-anhydride/request-sample

The Trimellitic Anhydride Production Cost Analysis Report meticulously examines the production processes and associated costs, providing a holistic view of the market landscape. From procurement to final product delivery, every aspect is scrutinized to empower businesses with actionable intelligence.

Procurement Resource Assessment of Trimellitic Anhydride Production Process

A critical aspect of the report is the procurement resource assessment, which evaluates the availability and sourcing dynamics of raw materials essential for Trimellitic Anhydride production. By analyzing procurement resources, businesses can optimize their supply chain strategies, ensuring uninterrupted production and cost efficiency.

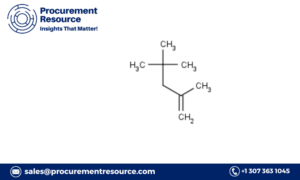

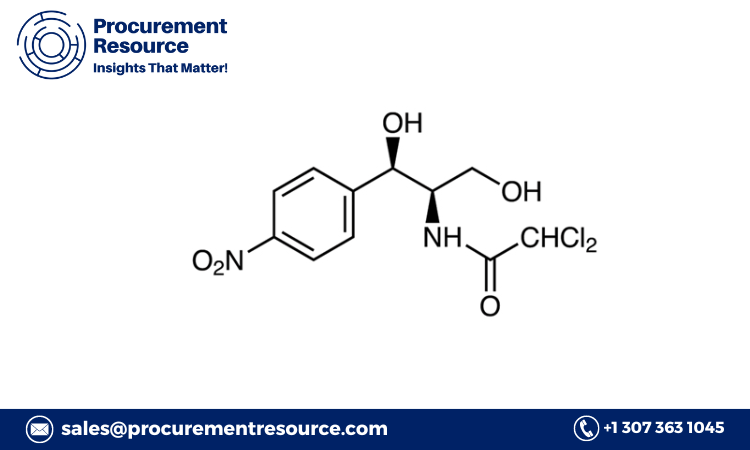

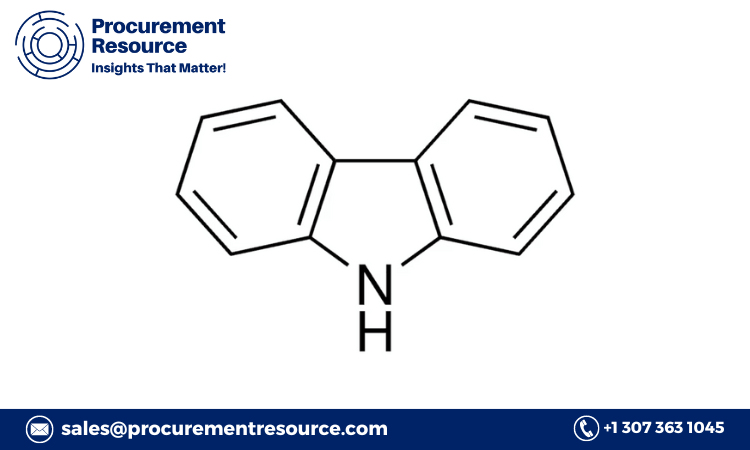

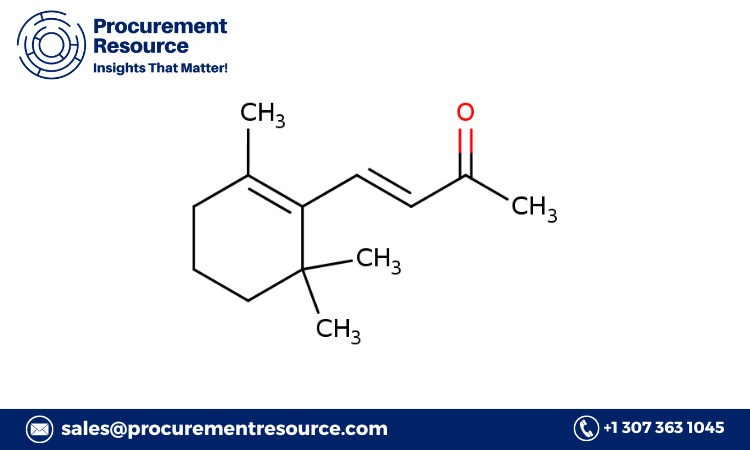

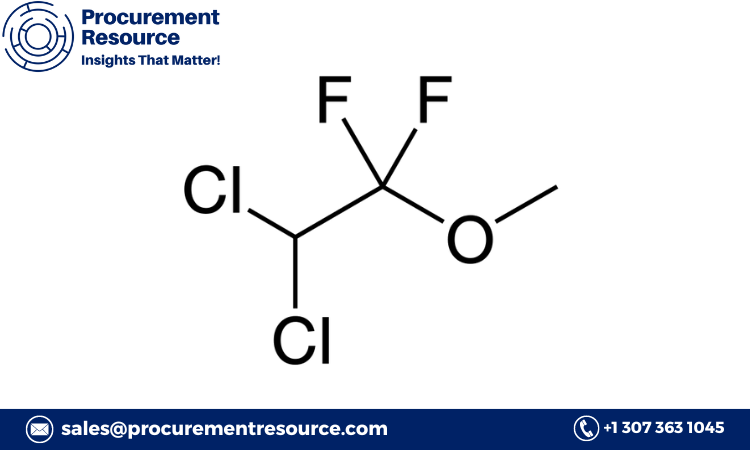

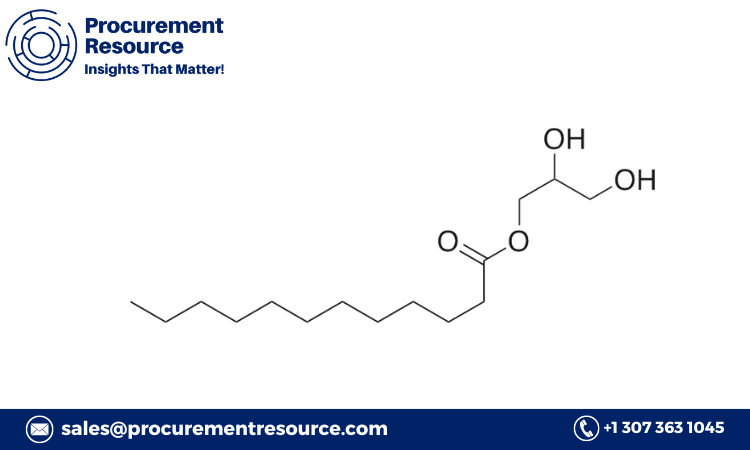

Product Definition

Trimellitic Anhydride, a vital chemical compound, finds widespread applications across various industries, including plastics, coatings, and pharmaceuticals. This report elucidates the characteristics and functionalities of Trimellitic Anhydride, providing clarity for stakeholders aiming to leverage its potential.

Market Drivers

The Trimellitic Anhydride Production Cost Analysis Report identifies and analyzes key market drivers influencing demand, pricing, and production dynamics. From evolving regulatory frameworks to shifting consumer preferences, understanding these drivers is paramount for adapting to market trends and gaining a competitive edge.

Raw Materials Requirements

An in-depth exploration of raw materials requirements forms the cornerstone of this report. By elucidating the composition and sourcing intricacies of raw materials, businesses can optimize procurement strategies, mitigate supply chain risks, and enhance cost-effectiveness in Trimellitic Anhydride production.

Costs and Key Process Information

Comprehensive cost analysis and insights into key process information are central to this report. By dissecting production costs and process efficiencies, businesses can identify areas for optimization, streamline operations, and bolster profitability in Trimellitic Anhydride production.

Looking for an Exhaustive and Personalized Report?

For businesses seeking an exhaustive and personalized report tailored to their specific needs, the Trimellitic Anhydride Production Cost Analysis Report is the definitive solution. Backed by meticulous research and expert analysis, this report promises to significantly substantiate your business strategies, enabling informed decision-making and sustainable growth.

In conclusion, the Trimellitic Anhydride Production Cost Analysis Report is poised to revolutionize the chemical industry landscape. With its comprehensive insights and actionable recommendations, it serves as a beacon of knowledge for businesses navigating the complexities of Trimellitic Anhydride production.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA