Corn starch, derived from the endosperm of the corn kernel, is a versatile product extensively used in food processing, pharmaceuticals, paper manufacturing, textiles, and various other industries. Its unique properties, such as thickening, binding, and stabilizing, make it a valuable ingredient in numerous applications. Understanding the price trends of corn starch is crucial for businesses and stakeholders involved in its production, procurement, and application. This blog delves into the recent corn starch price trends, forecast reports, market analysis, and the latest news affecting its market dynamics.

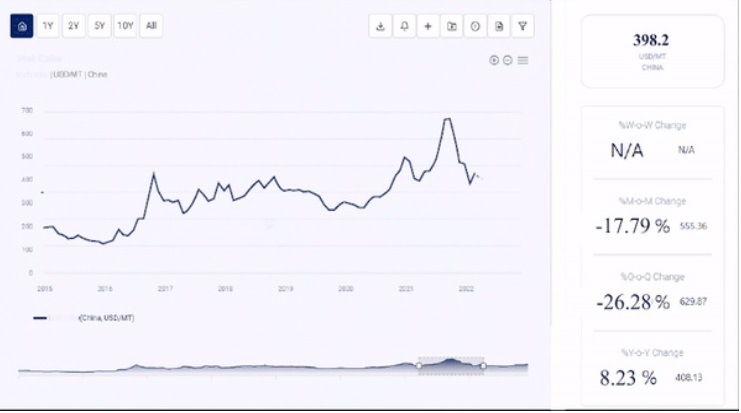

Corn Starch Price Trend

The price trend of corn starch is influenced by several factors, including the cost of raw corn, production processes, supply chain logistics, and market demand. In recent years, corn starch prices have exhibited significant fluctuations due to varying agricultural yields, climatic conditions, and economic factors.

Request For Sample: https://www.procurementresource.com/resource-center/corn-starch-price-trends/pricerequest

In 2023, corn starch prices saw a notable increase, driven by higher corn prices and increased demand from the food and beverage industry. The global supply chain disruptions caused by the COVID-19 pandemic also played a role in the price volatility, as transportation and labor shortages impacted production and distribution.

Moreover, the rising consumer preference for convenience foods and processed products has further fueled the demand for corn starch, thereby influencing its price. Technological advancements in corn starch production, aimed at improving efficiency and reducing costs, have also impacted the price trends. The adoption of new extraction and refining techniques has helped mitigate some of the cost pressures, contributing to a more stable pricing environment.

Forecast Report

The forecast for corn starch prices in the coming years suggests a mixed outlook, with several factors likely to influence the market dynamics. According to industry experts, the global corn starch market is expected to witness steady growth, driven by the increasing demand from various end-use industries.

One of the key factors expected to impact corn starch prices is the anticipated increase in corn production. Favorable weather conditions, advancements in agricultural practices, and government support for corn farming are likely to result in higher corn yields, subsequently affecting the availability and cost of raw corn.

Additionally, the growing trend of sustainable and eco-friendly products is expected to drive the demand for bio-based and renewable corn starch. This shift towards greener alternatives may lead to increased production costs, which could be reflected in the price trends.

However, uncertainties related to global trade policies, geopolitical tensions, and economic conditions could pose challenges to the corn starch market. Fluctuations in crude oil prices, which impact transportation and production costs, may also influence the future price trends.

Overall, while the corn starch market is poised for growth, stakeholders should remain vigilant about potential risks and opportunities that could affect the price trends.

Market Analysis

The corn starch market is segmented based on application, end-use industry, and region. Each segment contributes to the overall market dynamics and influences the price trends differently.

Application

Corn starch finds extensive application in various industries, including:

Food and Beverage

In the food and beverage industry, corn starch is used as a thickening agent, stabilizer, and emulsifier. It is a key ingredient in sauces, soups, bakery products, confectionery, and processed foods. The increasing demand for convenience foods and ready-to-eat products has driven the growth of corn starch in this sector.

Pharmaceuticals

In the pharmaceutical industry, corn starch is used as a binder, disintegrant, and filler in tablet formulations. Its biocompatibility and non-toxic nature make it an ideal excipient in drug manufacturing. The growing pharmaceutical sector, driven by the rising prevalence of chronic diseases and increasing healthcare expenditure, has boosted the demand for corn starch.

Industrial

In the industrial sector, corn starch is used in the production of adhesives, paper, textiles, and biodegradable plastics. Its properties, such as film-forming and adhesive strength, make it valuable in various manufacturing processes. The demand for sustainable and eco-friendly products has further driven the use of corn starch in industrial applications.

End-Use Industry

The corn starch market is also segmented based on end-use industries, including:

Food and Beverage

The food and beverage industry accounts for the largest share of the corn starch market, driven by the increasing consumer demand for processed and convenience foods. The growing trend of health and wellness has also led to the development of corn starch-based products with reduced fat and sugar content.

Pharmaceuticals

The pharmaceutical industry is a significant consumer of corn starch, primarily for tablet formulations. The rising demand for generic drugs and the expansion of the pharmaceutical sector in emerging markets have contributed to the growth of corn starch in this industry.

Industrial

The industrial sector, including paper, textiles, and packaging, represents a substantial market for corn starch. The demand for sustainable and biodegradable products has driven the adoption of corn starch in various industrial applications.

Region

The corn starch market is geographically segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. Each region exhibits distinct market dynamics and contributes to the overall price trends.

North America

North America is a significant market for corn starch, driven by the high demand from the food and beverage industry. The presence of major food processing companies and the increasing consumer preference for convenience foods have fueled the growth of corn starch in this region.

Europe

Europe is another prominent market for corn starch, primarily due to the growing trend of sustainable and organic products. The stringent regulations regarding food safety and quality have also contributed to the demand for high-quality corn starch in the region.

Asia-Pacific

Asia-Pacific is expected to witness the highest growth in the corn starch market, driven by the increasing population, urbanization, and rising disposable incomes. The expanding food and beverage industry, along with the growing pharmaceutical sector, has boosted the demand for corn starch in this region.

Latin America

Latin America represents a growing market for corn starch, primarily driven by the agricultural production of corn in countries like Brazil and Argentina. The increasing demand for processed foods and the growth of the industrial sector have contributed to the market growth.

Middle East and Africa

The Middle East and Africa region is also experiencing growth in the corn starch market, driven by the rising food processing industry and increasing consumer demand for convenience foods.

Latest News

The corn starch market is constantly evolving, with various developments and news impacting its price trends and market dynamics. Some of the latest news in the corn starch market include:

Technological Advancements

Technological advancements in corn starch production, such as the development of modified starches with enhanced properties, have significantly impacted the market. These innovations aim to improve the functionality and efficiency of corn starch in various applications, thereby influencing its price trends.

Sustainability Initiatives

The increasing focus on sustainability and environmental conservation has led to the development of bio-based and renewable corn starch products. Companies are investing in research and development to create eco-friendly alternatives, which are expected to drive the market growth and impact the price trends.

Trade Policies

Changes in global trade policies and regulations can significantly affect the corn starch market. Tariffs, import/export restrictions, and geopolitical tensions may impact the supply chain and influence the price trends.

Market Expansion

The expansion of key players in emerging markets and strategic collaborations with local manufacturers are driving the growth of the corn starch market. These initiatives aim to enhance production capacities, improve distribution networks, and cater to the increasing demand, thereby impacting the price trends.

Consumer Preferences

The evolving consumer preferences for clean label and natural ingredients have influenced the demand for corn starch. The growing awareness regarding health and wellness has led to the development of corn starch-based products with improved nutritional profiles, impacting the market dynamics and price trends.

Conclusion

The corn starch market is experiencing dynamic changes, driven by various factors such as raw material costs, technological advancements, and evolving consumer preferences. Understanding the price trends and market dynamics is crucial for businesses and stakeholders to make informed decisions. By keeping abreast of the latest news and developments, companies can navigate the market challenges and capitalize on growth opportunities in the corn starch industry.