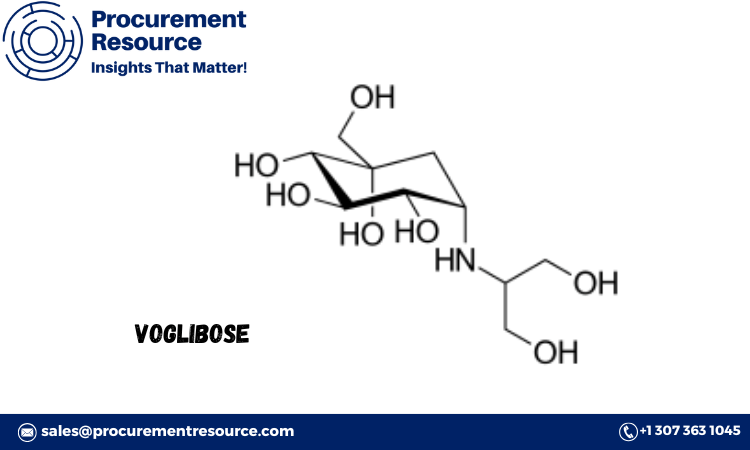

Voglibose, a widely used anti-diabetic medication, plays a crucial role in managing postprandial blood glucose levels in patients with type 2 diabetes. As the global prevalence of diabetes continues to rise, the demand for effective treatments like voglibose has surged. For pharmaceutical companies involved in the production and distribution of this drug, understanding voglibose production costs is essential for optimizing manufacturing processes and maintaining competitiveness in the market.

Request a Free Sample for Voglibose Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/voglibose/request-sample

In this article, we explore the key factors that contribute to the cost of producing voglibose, providing valuable insights into the various cost components that pharmaceutical companies must manage. These insights can help businesses refine their production processes, improve cost efficiency, and ultimately deliver more affordable medications to the market.

The Importance of Tracking Voglibose Production Costs

In a highly regulated and competitive pharmaceutical industry, tracking production costs is critical for ensuring profitability. For manufacturers of generic or branded voglibose, production costs can vary depending on raw material prices, labor, technological advancements, and regulatory requirements. Monitoring and optimizing these costs can help companies maintain profitability while meeting the growing demand for effective diabetes treatments.

Understanding voglibose production costs also helps manufacturers remain competitive in the marketplace. As healthcare providers and insurance companies push for cost-effective treatment options, pharmaceutical companies must be able to produce medications efficiently without sacrificing quality. A clear understanding of production costs allows companies to make strategic decisions about pricing, production volume, and market expansion.

Key Factors Affecting Voglibose Production Costs

Several factors influence the overall cost of voglibose production. These factors include the cost of raw materials, manufacturing processes, labor, and regulatory compliance. By understanding and managing these factors, pharmaceutical companies can optimize their production processes and reduce costs.

1. Raw Material Costs

The synthesis of voglibose involves various chemical compounds and intermediates, each contributing to the overall cost of production. The price of these raw materials can fluctuate due to changes in supply, demand, and market conditions. Additionally, the availability of high-quality raw materials can impact production efficiency and cost-effectiveness.

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/voglibose

Pharmaceutical companies must closely monitor global supply chains for raw materials to ensure a consistent and affordable supply. Any disruption in the availability of these materials can lead to increased production costs or delays in manufacturing, making it crucial to have reliable suppliers and contingency plans in place.

2. Labor and Operational Costs

Labor costs are another significant factor in voglibose production, especially in regions where highly skilled workers are required to operate advanced pharmaceutical equipment. The complexity of synthesizing voglibose and ensuring that it meets stringent regulatory standards often necessitates specialized labor, which can increase overall production costs.

In addition to direct labor costs, pharmaceutical companies must account for operational expenses such as facility maintenance, safety protocols, and the management of production lines. Optimizing labor efficiency and minimizing operational downtime are essential strategies for controlling production costs.

3. Manufacturing Process and Technology

The production of voglibose involves sophisticated chemical synthesis processes that require advanced equipment and technology. The efficiency of these manufacturing processes can have a significant impact on production costs. Pharmaceutical companies that invest in modern, energy-efficient manufacturing technologies can often reduce costs over time by improving yield, minimizing waste, and lowering energy consumption.

However, adopting new technologies often comes with upfront capital investment costs. While these investments can pay off in the long run by improving production efficiency, companies must carefully assess the cost-benefit ratio when deciding whether to implement new technologies.

4. Compliance with Regulatory Standards

As a pharmaceutical product, voglibose must meet rigorous regulatory standards set by agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Compliance with these standards is essential for ensuring product safety, efficacy, and quality. However, adhering to these regulations can add to production costs.

Pharmaceutical companies must invest in quality control systems, testing procedures, and certifications to ensure that their products comply with regulatory guidelines. The cost of these compliance measures can vary depending on the region and the specific requirements of the regulatory bodies involved.

5. Environmental and Waste Management Costs

The production of pharmaceutical compounds like voglibose often generates chemical waste, which must be disposed of in compliance with environmental regulations. Proper waste management and disposal procedures are essential for minimizing the environmental impact of production while adhering to regulatory standards.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/voglibose/ask-an-analyst

Pharmaceutical companies may face additional costs related to waste management, particularly if they are required to implement sustainable practices or invest in cleaner technologies to reduce emissions and environmental impact. These costs are an important consideration for companies looking to maintain environmentally responsible operations.

Breaking Down the Costs: A Detailed Analysis of Voglibose Production

Voglibose production costs can be broken down into several key categories:

- Raw Material Costs: This category includes the cost of sourcing high-quality chemical compounds used in the synthesis of voglibose. The price of these materials is subject to market fluctuations and can vary depending on global supply and demand.

- Manufacturing Costs: Manufacturing costs encompass the expenses associated with the production process, including the cost of energy, machinery, equipment, and labor. Efficient production processes and the use of advanced technologies can help reduce manufacturing costs over time.

- Quality Control and Testing: Ensuring the safety and efficacy of voglibose requires rigorous quality control procedures, including testing for purity, potency, and stability. These quality assurance processes are essential for meeting regulatory requirements but add to the overall production costs.

- Labor and Operational Costs: Highly skilled workers are needed to oversee the production of voglibose, operate sophisticated equipment, and manage compliance with safety protocols. Labor and operational costs can vary based on the region and the scale of production.

- Regulatory Compliance: Pharmaceutical companies must adhere to strict regulatory guidelines, which may involve additional costs for quality control, testing, documentation, and certification. Meeting these standards is essential for ensuring that voglibose can be marketed and sold in various regions.

- Environmental and Waste Management: Proper waste disposal and environmental management are critical aspects of pharmaceutical production. Companies must invest in waste management systems and ensure compliance with environmental regulations to minimize the environmental impact of voglibose production.

The Importance of Detailed Voglibose Production Cost Reports

For pharmaceutical companies involved in voglibose production, having access to detailed cost reports is essential for managing expenses, optimizing processes, and improving profitability. Detailed voglibose production cost reports provide valuable insights into the specific cost components involved in the production process, allowing companies to identify areas where they can reduce costs and improve efficiency.

Here’s how detailed production cost reports can benefit businesses:

- Cost Management: By understanding the specific cost components involved in voglibose production, companies can better manage their expenses and identify opportunities to reduce costs without compromising quality.

- Efficiency Optimization: Detailed cost reports can help companies identify inefficiencies in their production processes and implement strategies to improve yield, reduce waste, and minimize energy consumption.

- Risk Mitigation: Pharmaceutical production is subject to various risks, including raw material shortages, regulatory changes, and market fluctuations. Detailed cost reports provide insights into potential risks and offer strategies for mitigating these challenges.

- Strategic Decision-Making: Whether expanding production capacity, investing in new technologies, or entering new markets, understanding production costs is essential for making informed strategic decisions. Cost reports provide a clear picture of the financial requirements for scaling operations or diversifying product lines.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/voglibose/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA & Canada: +1 307 363 1045

UK: +44 7537171117

Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA