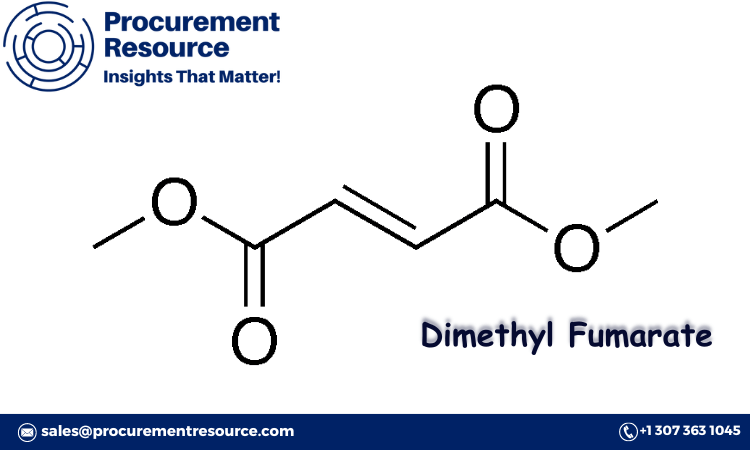

Dimethyl fumarate (DMF), widely recognized for its application in pharmaceuticals, coatings, and chemical manufacturing, is increasingly significant in various industries due to its versatile properties. As demand for DMF rises, companies involved in its production need in-depth insights into the associated costs to maintain competitiveness. Procurement Resource offers detailed Dimethyl Fumarate Production Cost Reports, empowering businesses to understand, control, and optimize production costs to stay ahead in the dynamic market landscape.

Why Dimethyl Fumarate is Important

Dimethyl fumarate, a fumaric acid ester, is primarily used in medical applications, particularly in treating multiple sclerosis and psoriasis. In addition to its role in the pharmaceutical industry, DMF is also employed as an additive in coatings and polymers due to its antioxidant properties. Given its wide array of applications, understanding the cost structure behind DMF production is essential for manufacturers to ensure efficient resource allocation and maintain profitability.

Request a Free Sample for Dimethyl Fumarate Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/dimethyl-fumarate/request-sample

Key Factors Influencing Dimethyl Fumarate Production Costs

The production of dimethyl fumarate involves several factors that influence its cost, including raw materials, labor, energy, and environmental compliance. Here’s a breakdown of the main elements affecting DMF production costs:

1. Raw Material Costs

Dimethyl fumarate is synthesized from fumaric acid and methanol, with these raw materials representing a significant portion of production costs. Fluctuations in the price of fumaric acid and methanol are influenced by factors such as feedstock availability, production capacity, and energy costs, which are critical for companies to monitor. Efficient procurement strategies and reliable supplier relationships help manufacturers manage raw material costs effectively.

2. Processing and Synthesis Costs

The production of DMF typically involves esterification, purification, and crystallization processes, which are capital-intensive and require specialized equipment. The cost of energy, catalysts, and other processing agents can significantly impact overall production costs. Companies that invest in optimized synthesis methods or advanced catalytic processes can enhance efficiency, reducing both energy consumption and raw material waste, thus managing costs more effectively.

3. Labor and Operational Costs

Labor expenses play a crucial role in DMF production, particularly as skilled technicians are required to oversee production processes, maintain equipment, and ensure quality standards. Labor costs can vary by region, and operational expenses, such as utilities, facility maintenance, and safety protocols, also affect production costs. Efficient labor management and well-organized operational workflows help minimize these expenses, improving cost efficiency.

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/dimethyl-fumarate

4. Technology and Equipment Maintenance

Producing dimethyl fumarate necessitates high-tech equipment for synthesis, purification, and quality control. This equipment requires substantial initial investment and ongoing maintenance, which contribute to production costs. Companies must balance the need for advanced technology with maintenance expenses to ensure consistent product quality and avoid operational interruptions. Advanced, efficient systems may incur higher initial costs but result in long-term savings and improved productivity.

5. Quality Control and Compliance

Quality assurance is essential in DMF production, particularly given its medical applications. Strict quality control measures, including purity testing and regulatory compliance, add to production costs but are critical for maintaining safety and efficacy. Regulatory standards, such as those from the FDA and other health authorities, necessitate adherence to high standards. Non-compliance can lead to penalties and recalls, underscoring the importance of stringent quality control and regulatory alignment in cost management.

6. Environmental and Regulatory Costs

Dimethyl fumarate production must adhere to environmental regulations, especially given the by-products generated during synthesis. Compliance with environmental standards includes managing waste disposal, controlling emissions, and ensuring water treatment. Implementing sustainable practices, such as waste recycling or pollution control, can add to production expenses but also enhances brand reputation and mitigates legal risks. Companies that proactively manage their environmental footprint often benefit from long-term cost savings and improved market perception.

How Procurement Resource’s Dimethyl Fumarate Production Cost Reports Can Benefit Your Business

At Procurement Resource, we offer Dimethyl Fumarate Production Cost Reports that provide comprehensive insights into production expenses, helping businesses manage costs more effectively and gain a competitive edge. Here’s what our reports include:

- Detailed Cost Breakdown

Our Dimethyl Fumarate Production Cost Reports provide a complete breakdown of production costs, covering everything from raw materials and labor to synthesis, equipment maintenance, and regulatory compliance. This thorough analysis helps businesses understand resource allocation and identify areas where costs can be minimized.

- Real-Time Market Data and Trends

The DMF market is influenced by multiple factors, including raw material availability, energy prices, and regulatory changes. Our reports offer real-time data on market trends and insights into industry developments, enabling companies to respond effectively to shifting market conditions.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/dimethyl-fumarate/ask-an-analyst

- Price Trends and Analysis

Our reports track pricing trends for raw materials, energy, and other production inputs, allowing companies to make informed procurement decisions. With historical price data and analysis, companies can anticipate cost changes and adapt their strategies to maintain stability in a fluctuating market environment.

- Benchmarking and Industry Comparison

Our reports feature benchmarking data, enabling companies to compare their production costs with industry standards. Identifying cost discrepancies allows businesses to make strategic adjustments to improve efficiency, reduce expenses, and optimize resource utilization.

- Procurement and Supply Chain Insights

Effective procurement and supply chain management are essential to keep dimethyl fumarate production costs competitive. Our reports provide insights into raw material sourcing, supplier management, and logistics strategies to help businesses build resilient supply chains and control expenses.

Stay Competitive in the DMF Market with Procurement Resource

Partnering with Procurement Resource gives you access to in-depth industry intelligence that helps you stay competitive in the DMF market. Our Dimethyl Fumarate Production Cost Reports are designed to streamline decision-making, enhance supply chain efficiency, and support cost management.

We understand that each business has unique needs, and our reports are customizable to align with your goals. Whether you’re looking to optimize costs, improve quality, or navigate regulatory requirements, our team of expert analysts is here to assist you at every step.

Request Your Free Sample Report Today

Are you ready to take control of your DMF production costs? Request a free sample report from Procurement Resource to see how our insights can help your business. Our reports equip you with the data and tools to enhance cost efficiency, improve profitability, and succeed in the competitive DMF market.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/dimethyl-fumarate/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA copyright: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA