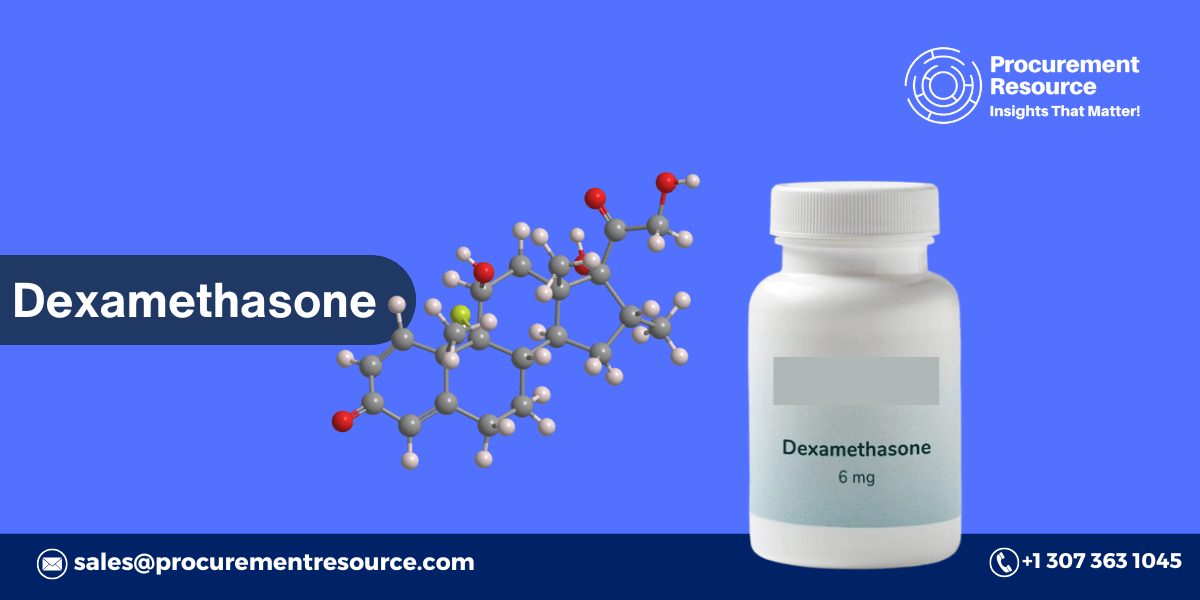

In the fast-evolving world of pharmaceuticals, the dexamethasone production cost plays a critical role in ensuring the availability of this vital medication. As a potent corticosteroid, dexamethasone is widely used in the treatment of numerous conditions, including inflammatory diseases, allergies, autoimmune disorders, and even as part of COVID-19 management protocols. Understanding the costs involved in producing dexamethasone is crucial for pharmaceutical companies, healthcare providers, and policymakers.

At Procurement Resource, we are committed to helping businesses and stakeholders make informed decisions by providing detailed insights into the cost structure of dexamethasone production. Having reliable and comprehensive cost data allows companies to optimize operations, remain competitive, and meet regulatory standards.

This article provides a detailed breakdown of dexamethasone production costs, the key factors influencing these costs, and how manufacturers can optimize their processes to reduce expenses while maintaining high-quality standards.

Request a Free Sample For Dexamethasone Production Cost- https://www.procurementresource.com/production-cost-report-store/dexamethasone/request-sample

The Importance of Dexamethasone in the Pharmaceutical Industry

- Versatile Medical Applications:

- Dexamethasone is used to treat a wide range of conditions, from severe allergies and asthma to arthritis, inflammatory bowel disease, and certain cancers.

- It is also employed in the treatment of brain swelling, adrenal insufficiency, and as an adjunct therapy in chemotherapy.

- Global Demand Surge:

- The COVID-19 pandemic significantly increased the demand for dexamethasone as it was identified as an effective treatment for severe respiratory complications caused by the virus.

- Generic Availability:

- Dexamethasone is available as a generic drug, making it a cost-effective solution for healthcare providers worldwide.

Given its critical role in healthcare, understanding the production cost of dexamethasone is essential for manufacturers and suppliers aiming to maintain affordability and accessibility.

Understanding the Factors Behind Dexamethasone Production Costs

1. Raw Material Costs

- Active Pharmaceutical Ingredient (API):

- The production of dexamethasone relies on specific steroidal intermediates and reagents, such as cortisone or hydrocortisone.

- Impact on Costs:

- Fluctuations in the prices of raw materials, driven by global supply chain dynamics and demand, significantly impact production expenses.

Read Full Report – https://www.procurementresource.com/production-cost-report-store/dexamethasone

2. Energy Costs

- Energy Requirements:

- The synthesis of dexamethasone involves multiple energy-intensive chemical processes, including oxidation, hydroxylation, and purification.

- Impact on Costs:

- Rising energy costs, particularly for electricity and natural gas, contribute to higher operational expenses.

3. Labor and Operational Costs

- Labor Involvement:

- Skilled chemists and technicians are required to manage complex chemical reactions, monitor quality control, and ensure regulatory compliance.

- Impact on Costs:

- Labor expenses vary depending on the location of manufacturing facilities and the degree of automation in operations.

4. Technological Advances and Maintenance

- Modern Production Techniques:

- Advanced technologies, such as continuous manufacturing and high-performance chromatography, improve efficiency but require significant investment.

- Maintenance Costs:

- Regular maintenance of reactors, filtration systems, and analytical equipment adds to operational costs.

5. Environmental and Regulatory Compliance

- Stringent Regulations:

- Dexamethasone production must comply with Good Manufacturing Practices (GMP) and regulations from agencies like the FDA, EMA, and WHO.

- Impact on Costs:

- Investments in waste management, emission controls, and documentation processes are necessary to meet environmental and safety standards.

The Dexamethasone Production Process and Cost Breakdown

The production of dexamethasone involves several complex steps, each contributing to its overall cost. Here’s an overview:

1. Synthesis of Key Intermediates

- Process:

- Steroidal precursors such as hydrocortisone are chemically modified through oxidation and hydroxylation reactions to form the core structure of dexamethasone.

- Cost Factors:

- Raw material prices, catalyst expenses, and energy consumption.

2. API Production

- Process:

- The intermediate undergoes further chemical reactions, including halogenation and isomerization, to achieve the desired pharmacological properties of dexamethasone.

- Cost Factors:

- High-quality reagents, energy for precise reaction conditions, and skilled labor.

3. Purification and Crystallization

- Process:

- The crude product is purified through chromatography and crystallization to meet pharmaceutical-grade standards.

- Cost Factors:

- Solvent recovery, energy for cooling and heating, and waste disposal systems.

4. Formulation Development

- Process:

- The purified API is formulated into tablets, injections, or oral solutions with excipients and stabilizers.

- Cost Factors:

- Costs of excipients, manufacturing equipment, and formulation-specific processes.

5. Quality Assurance

- Process:

- Each batch undergoes rigorous testing for purity, potency, and stability to ensure compliance with pharmacopoeial standards.

- Cost Factors:

- Analytical equipment, skilled personnel, and documentation.

6. Packaging and Distribution

- Process:

- The final product is packaged into appropriate containers, labeled, and distributed to hospitals, pharmacies, or wholesalers.

- Cost Factors:

- Packaging materials, labor for handling, and transportation logistics.

Market Trends Impacting Dexamethasone Production Costs

1. Rising Global Demand

- The increasing prevalence of chronic inflammatory diseases and the ongoing use of dexamethasone in COVID-19 treatment have boosted demand, impacting raw material availability and pricing.

2. Supply Chain Challenges

- Disruptions in global supply chains, particularly for raw materials, have contributed to price volatility and increased production costs.

3. Generic Market Competition

- The availability of generic dexamethasone has heightened price competition, pushing manufacturers to optimize production processes and reduce costs.

4. Regulatory Pressures

- Enhanced regulatory scrutiny, particularly for quality control and environmental compliance, adds complexity and cost to the production process.

Strategies to Optimize Dexamethasone Production Costs

- Efficient Raw Material Sourcing

- Establishing long-term contracts with reliable suppliers and exploring alternative sources for key raw materials can stabilize costs.

- Energy Optimization

- Investing in energy-efficient equipment and adopting renewable energy sources can reduce operational expenses.

- Process Improvement

- Implementing advanced synthesis techniques and solvent recovery systems can enhance yield and minimize waste.

- Automation and Digitalization

- Incorporating automated systems and digital tools for monitoring and quality control reduces labor costs and improves precision.

- Sustainability Initiatives

- Adopting eco-friendly production methods and securing certifications for sustainable practices can improve market competitiveness.

How Procurement Resource’s Dexamethasone Production Cost Reports Can Help

At Procurement Resource, we provide comprehensive cost analysis and insights to support pharmaceutical companies in optimizing their operations. Here’s how our reports can assist:

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/dexamethasone/ask-an-analyst

- Detailed Cost Breakdown

- Analysis of raw material, labor, energy, and operational costs for each stage of production.

- Market Trends and Forecasts

- Insights into demand patterns, regulatory changes, and future price projections.

- Optimization Recommendations

- Strategies for improving efficiency and reducing costs while maintaining quality standards.

- Regulatory Compliance Guidance

- Insights into cost-effective approaches to meet global regulatory requirements.

- Future Projections

- Reliable forecasts to support long-term planning and decision-making.

The production cost of dexamethasone is influenced by various factors, including raw material prices, energy consumption, labor expenses, and regulatory requirements. As a critical medication in global healthcare, optimizing its production cost is essential to ensure affordability and accessibility. By leveraging actionable insights and adopting efficient practices, manufacturers can navigate challenges and capitalize on growth opportunities in the pharmaceutical market.

Request Your Free Sample Report Today to gain expert insights into dexamethasone production costs and strategies for optimizing your operations.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/dexamethasone/request-sample

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA