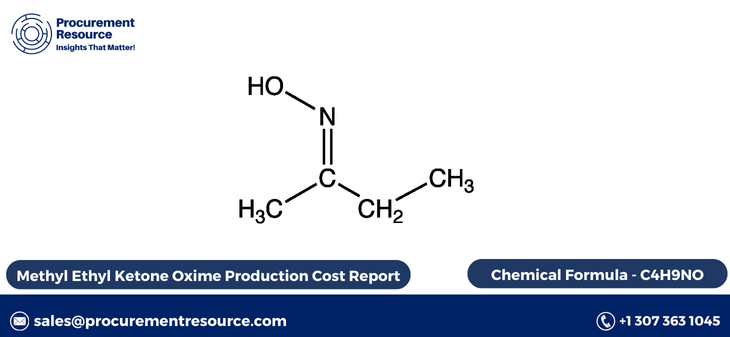

Methyl Ethyl Ketone Oxime (MEKO) is a versatile chemical compound widely utilized across diverse industries. Known for its properties as an anti-skinning agent in paints and coatings, MEKO is a crucial element in enhancing product longevity and quality. Its production process requires precision, efficiency, and adherence to industrial standards, making it essential to understand the associated trends, labor costs, and pre-feasibility considerations.

This blog delves into the production process of Methyl Ethyl Ketone Oxime, highlighting its significance and the indispensable role of detailed reports from procurement resources in making informed decisions for businesses and stakeholders.

Why Methyl Ethyl Ketone Oxime Production Process Matters

Essential Industrial Application

MEKO finds primary applications in the paint and coatings industry, where it prevents premature skinning of paint in cans, ensuring ease of application and longer shelf life. It also plays a role in adhesives, sealants, and other industrial products. The demand for MEKO is driven by its irreplaceable functionality, making its production process a critical area of study.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/methyl-ethyl-ketone-oxime/request-sample

Pre-Feasibility Analysis

A comprehensive pre-feasibility analysis is the cornerstone of any successful production endeavor. For MEKO, this includes understanding the costs of raw materials such as methyl ethyl ketone and hydroxylamine, utilities like water and energy, and logistics. Additionally, environmental and regulatory compliance, production technology, and scalability are critical factors that influence the viability of MEKO production.

Industrial Trends

Global industrial trends in MEKO production are influenced by:

- Evolving Regulations: Stricter environmental norms are pushing manufacturers to adopt greener production methods and minimize hazardous waste.

- Market Demand: Rapid growth in construction, automotive, and industrial sectors is boosting the demand for paints and coatings, indirectly influencing MEKO’s demand.

- Technological Advancements: Innovations in chemical synthesis and production technologies are making the MEKO production process more efficient and cost-effective.

Labor Charges

Labor costs are a significant component of the production process. Variations in labor costs across regions affect the overall profitability of manufacturing MEKO. Skilled labor, training, and adherence to safety standards are crucial factors that need detailed evaluation during pre-feasibility studies.

The Power of Procurement Resource Methyl Ethyl Ketone Oxime Production Process Reports

Procurement Resource is a trusted name in delivering precise, well-researched production process reports for a wide range of chemicals and industrial products, including MEKO. These reports serve as a valuable resource for businesses, offering a detailed overview of production methodologies, cost breakdowns, market dynamics, and trends.

Read Full Report – https://www.procurementresource.com/production-cost-report-store/methyl-ethyl-ketone-oxime

Key Features of the Reports

- In-depth Process Analysis: Comprehensive insights into the chemical synthesis and production methods used for MEKO.

- Cost Structure Detailing: Detailed breakdown of raw material costs, labor expenses, utility consumption, and overheads.

- Market Trends and Drivers: Information on industrial and economic factors impacting the MEKO market.

- Environmental and Safety Considerations: Guidelines to meet environmental regulations and ensure workplace safety during production.

- Technological Insights: Highlights on innovations that can optimize efficiency and reduce costs in the MEKO production process.

Benefits for Stakeholders

By leveraging Procurement Resource reports, stakeholders can:

- Make informed decisions regarding investments in MEKO production.

- Identify cost-saving opportunities in raw materials, labor, and logistics.

- Develop sustainable production strategies in compliance with regulatory requirements.

- Stay ahead of industrial trends to gain a competitive edge.

How Procurement Resource Can Help You

Whether you are planning to establish a MEKO production unit, optimize existing operations, or evaluate investment opportunities, Procurement Resource can provide the actionable insights you need.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/methyl-ethyl-ketone-oxime/ask-an-analyst

Customized Solutions

Procurement Resource tailors its reports to meet the unique requirements of its clients. From detailed feasibility studies to cost trend analyses, the solutions are designed to address specific business challenges.

Expert Insights

Each report is crafted by industry experts with years of experience in chemical production and market analysis. Their expertise ensures the accuracy and relevance of the information presented.

Comprehensive Cost Modelling

A detailed understanding of cost structures helps businesses minimize expenses while maintaining high-quality production. Procurement Resource reports provide clarity on all cost components, helping businesses achieve efficiency and profitability.

Supporting Sustainability

The company emphasizes sustainable production practices by offering insights into green technologies and waste reduction methods, enabling businesses to align with environmental goals.

Request Your Free Sample Report Today!

Procurement Resource offers a complimentary sample report to give you a glimpse into the depth and quality of their research. By requesting a free sample report, you can:

- Understand the scope of the Methyl Ethyl Ketone Oxime Production Process Report.

- Evaluate the comprehensiveness of cost analysis and industrial trends.

- Gain confidence in making well-informed decisions for your business.

How to Request

Requesting a free sample is simple. Visit the Procurement Resource website, navigate to the MEKO production process report page, and click on the “Request Free Sample” option. Fill out a brief form, and you’ll receive a tailored sample report in no time.

Request Your Free Sample Report – https://www.procurementresource.com/production-cost-report-store/methyl-ethyl-ketone-oxime/request-sample

The production process of Methyl Ethyl Ketone Oxime is intricate and influenced by numerous factors such as cost, labor, and industrial trends. With the support of Procurement Resource’s detailed reports, businesses can navigate these complexities effectively. From pre-feasibility studies to market trend analyses, these reports provide a comprehensive roadmap for achieving operational success.

Invest in the future of your business by leveraging the power of detailed production process reports. Request your free sample today and take the first step toward informed decision-making and sustainable growth!

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA