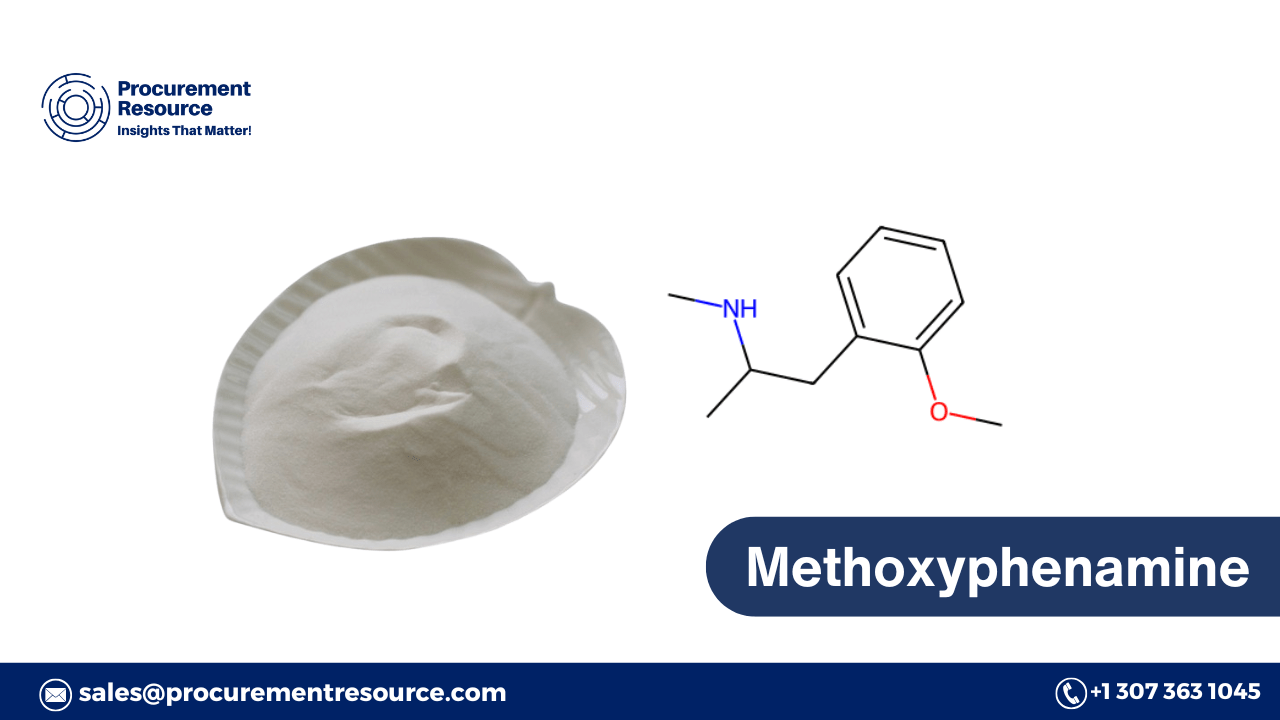

In the fast-evolving pharmaceutical industry, Methoxyphenamine Production Cost plays a critical role in determining profitability, scalability, and market competitiveness. Methoxyphenamine, a widely utilised compound in medicinal chemistry, finds applications in respiratory treatments and decongestants. Its significance in healthcare has driven demand, making an understanding of its production costs vital for pharmaceutical companies, researchers, and investors.

Methoxyphenamine production is a multi-step process requiring precise formulations, advanced technology, and strict adherence to regulatory guidelines. The ability to produce this compound cost-effectively while maintaining high-quality standards can be the differentiator in the competitive pharmaceutical landscape. This article explores the various factors influencing methoxyphenamine production cost, offering insights into raw materials, energy requirements, labour, technology, and environmental considerations.

Request a Free Sample For Methoxyphenamine Production Cost Reports — https://www.procurementresource.com/production-cost-report-store/methoxyphenamine/request-sample

Factors Affecting Methoxyphenamine Production Cost

1. Raw Material Costs

- Base Chemicals: Methoxyphenamine production involves a combination of chemical precursors. Commonly used starting materials include aniline derivatives, methoxybenzyl alcohol, and other intermediates. The cost of these raw materials depends on their availability, purity levels, and global market trends.

- Catalysts and Solvents: Synthesis processes often rely on catalysts and solvents, which facilitate chemical reactions. Solvents like ethanol, acetone, or toluene are frequently used, and their procurement costs can vary significantly depending on supplier contracts and shipping logistics.

- Quality Assurance: The cost of ensuring raw materials meet pharmaceutical-grade standards is significant. Regular testing, certification, and sourcing from approved vendors contribute to this aspect of production costs.

Read Full Report — https://www.procurementresource.com/production-cost-report-store/methoxyphenamine

2. Energy Costs

- Heating and Cooling Requirements: Methoxyphenamine synthesis often involves temperature-controlled reactions, which necessitate precise heating and cooling systems. The energy required to maintain these systems constitutes a major cost driver.

- Electricity and Fuel Costs: Manufacturing facilities rely on uninterrupted electricity and fuel supplies. Regional energy tariffs, renewable energy adoption, and infrastructure efficiency directly impact the overall production costs.

- Recycling Energy: Some facilities invest in energy recovery systems to optimise efficiency. While these systems reduce long-term costs, their initial setup requires significant capital.

3. Labour and Operational Costs

- Skilled Workforce: Pharmaceutical manufacturing requires skilled chemists, engineers, and technicians. The salaries, training costs, and benefits for these professionals represent a large portion of operational expenses.

- Automation: To reduce dependency on manual labour, many facilities invest in automation technologies. While this can lower recurring labour costs, the upfront investment in automated machinery and software can be substantial.

- Quality Control and Compliance: Ensuring adherence to Good Manufacturing Practices (GMP) and regulatory guidelines requires dedicated teams for quality assurance, safety inspections, and process validation.

4. Technological Advances and Maintenance

- Synthesis Methods: Modern synthesis techniques such as green chemistry and biocatalysis are gaining traction in methoxyphenamine production. While these methods are cost-effective and environmentally friendly, their implementation may involve high initial costs for R&D and equipment.

- Equipment Upkeep: Routine maintenance of reactors, distillation units, and purification systems is essential for uninterrupted operations. Maintenance costs include spare parts, technician fees, and downtime-related expenses.

- Process Optimisation: Continuous improvements in production processes, such as reducing reaction times or increasing yield efficiency, can significantly lower costs. However, such advancements often require substantial investment in research and pilot testing.

5. Environmental and Regulatory Costs

- Waste Management: The chemical synthesis of methoxyphenamine generates waste by-products, which must be managed in compliance with environmental regulations. Investing in waste treatment plants and adopting eco-friendly disposal methods adds to production costs.

- Emissions Control: Manufacturing facilities must monitor and control emissions of volatile organic compounds (VOCs) and other pollutants. Advanced filtration systems and emission reduction technologies represent an ongoing expense.

- Regulatory Compliance: Compliance with pharmaceutical regulatory standards such as those set by the FDA or EMA is non-negotiable. Costs associated with certifications, audits, and documentation contribute significantly to the overall production budget.

Reducing Methoxyphenamine Production Costs

Manufacturers can adopt various strategies to minimise production costs without compromising on quality:

1. Raw Material Sourcing

- Partnering with bulk suppliers and exploring local sourcing options can lower material costs.

- Investing in long-term contracts to hedge against price volatility.

2. Energy Efficiency

- Upgrading to energy-efficient machinery and integrating renewable energy sources.

- Implementing energy monitoring systems to identify and rectify inefficiencies.

3. Optimising Labour

- Leveraging automation for repetitive tasks to reduce labour dependency.

- Upskilling the workforce to improve productivity and reduce errors.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/methoxyphenamine/ask-an-analyst

4. Sustainable Practices

- Adopting green chemistry principles to minimise waste and reduce environmental compliance costs.

- Recycling solvents and catalysts to lower raw material expenses.

5. Technological Innovation

- Investing in research to optimise reaction pathways and improve yields.

- Collaborating with academic institutions and research organisations for cost-effective process innovations.

Why Methoxyphenamine Production Cost Reports Are Essential

Access to detailed cost reports is invaluable for stakeholders in the methoxyphenamine production chain. These reports provide:

- Market Insights: Understanding cost structures helps companies forecast market trends and price products competitively.

- Investment Decisions: Cost data assists investors in identifying profitable ventures and mitigating risks.

- Process Benchmarking: Comparing production costs with industry standards helps identify areas for improvement.

- Strategic Planning: Data-driven decisions on scaling operations or entering new markets become feasible with detailed cost reports.

Methoxyphenamine production costs are influenced by multiple factors, including raw material prices, energy requirements, labour costs, technological investments, and regulatory compliance. For manufacturers, understanding these cost drivers is essential for optimising operations, improving profitability, and staying competitive in the pharmaceutical industry.

By adopting sustainable practices, leveraging technological advancements, and maintaining strict quality controls, manufacturers can navigate the challenges of methoxyphenamine production efficiently. Access to accurate, data-driven production cost reports enables businesses to make informed decisions and stay ahead in this dynamic market.

Request a Free Sample — https://www.procurementresource.com/production-cost-report-store/methoxyphenamine/request-sample

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA