In the ever-evolving pharmaceutical industry, understanding the production costs of active pharmaceutical ingredients (APIs) is critical for maintaining competitiveness. Iopanoic acid, an iodine-containing compound, is widely used in the treatment of thyroid conditions and as a diagnostic tool for imaging purposes. For companies involved in the manufacturing and distribution of Iopanoic acid, gaining insights into production costs is essential for streamlining operations, optimizing costs, and making informed procurement decisions. At Procurement Resource, we offer detailed, data-driven Iopanoic Acid Production Cost Reports designed to help businesses navigate the complexities of cost management in this specialized field.

Why Iopanoic Acid is Important

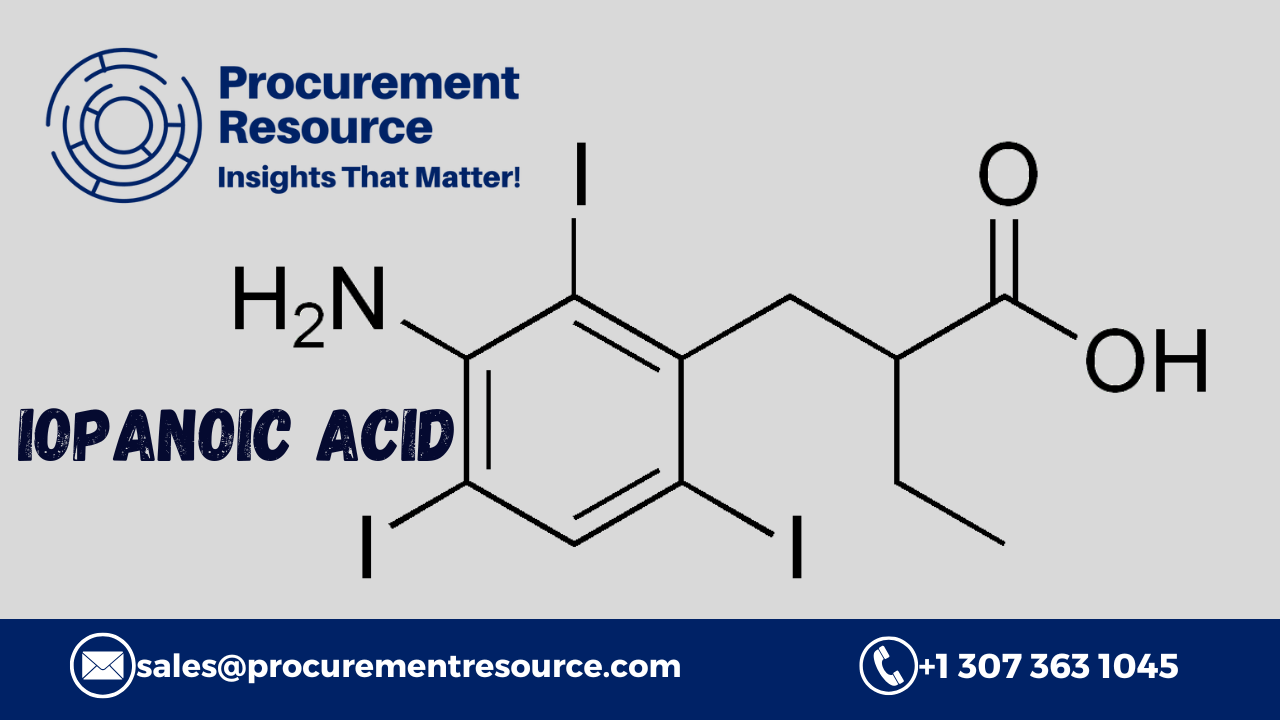

Iopanoic acid (C₁₆H₁₉I₃NO₄) is primarily used in the treatment of hyperthyroidism and as an imaging agent in medical diagnostics. It is particularly effective in blocking thyroid hormone production and is used in the diagnostic imaging of the thyroid gland. Its iodine content is crucial for its ability to influence thyroid function, making it an essential drug for thyroid management and diagnostic imaging.

Beyond its medical applications, Iopanoic acid has also been studied for its potential use in other areas, including cancer research and treatment. As the global demand for effective thyroid medications and diagnostic tools grows, understanding the costs involved in Iopanoic acid production becomes even more critical for companies looking to maintain a competitive edge in the market.

Request a Free Sample for Iopanoic Acid Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/iopanoic-acid/request-sample

Understanding the Factors Behind Iopanoic Acid Production Costs

The production of Iopanoic acid involves several stages, including the synthesis of the iodine-containing compound, purification, and formulation into the final product. Several factors influence the cost of Iopanoic acid production, from raw material prices to energy consumption, labor costs, and technological innovations. Below is a breakdown of the key factors that contribute to the overall production cost of Iopanoic acid:

1. Raw Material Costs

The key raw materials used in Iopanoic acid production include iodine and various organic compounds that are chemically modified during synthesis. The cost of iodine, a critical component in the production of Iopanoic acid, can fluctuate based on global supply and demand, geopolitical factors, and mining operations. The costs of other chemicals and reagents, as well as solvents used in the synthesis and purification of the final product, also add to the raw material expenses. Given that raw materials often account for a significant portion of production costs, fluctuations in their prices can have a substantial impact on overall manufacturing expenses.

2. Energy Costs

Energy consumption is another critical factor in Iopanoic acid production, as the synthesis process requires significant heat and electricity for reactions, distillation, and purification. The production process, which typically involves the use of high-temperature reactions, consumes large amounts of energy, which can account for a substantial portion of production costs. Additionally, energy prices can vary based on the region, which means that companies need to carefully manage energy efficiency and explore cost-saving strategies, such as adopting renewable energy sources, to reduce the impact of rising energy prices.

3. Labor and Operational Costs

The production of Iopanoic acid requires skilled workers, including chemists, chemical engineers, and quality control specialists, to oversee the manufacturing process. Labour costs can vary depending on the location of the production facility and the level of expertise required. In addition to wages, companies also need to account for operational costs related to facility maintenance, compliance with regulatory standards, and the implementation of safety protocols. Maintaining high standards in production quality, especially in the pharmaceutical sector, is crucial for ensuring the safety and efficacy of the final product.

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/iopanoic-acid

4. Technological Advances and Maintenance

Technological innovations that improve the efficiency of the production process, such as more advanced synthesis methods or automated systems for monitoring and control, can help reduce production costs in the long term. However, adopting these technologies often requires significant capital investment. Additionally, regular maintenance of production equipment is essential for ensuring smooth operations and avoiding costly downtime. This can add to the overall operational costs, though the long-term benefits of increased efficiency and reduced waste may offset these expenses.

5. Regulatory and Compliance Costs

The pharmaceutical industry is highly regulated to ensure the safety, efficacy, and quality of products. Iopanoic acid production must comply with stringent quality control measures, including adherence to Good Manufacturing Practices (GMP), safety standards, and environmental regulations. Ensuring compliance with these regulations often requires investments in quality control systems, testing, and certification, all of which contribute to production costs. Additionally, meeting environmental regulations related to waste disposal and emissions control adds further costs to the manufacturing process.

6. Packaging and Distribution Costs

Once produced, Iopanoic acid must be carefully packaged to maintain its stability and prevent contamination. Packaging materials, such as bottles, blister packs, and labels, are an essential part of the cost structure. Furthermore, the distribution process, including transportation, storage, and logistics, plays a significant role in determining the final cost of the product. Efficient packaging and distribution strategies are crucial to managing these costs and ensuring that the product reaches customers in a timely and cost-effective manner.

How Procurement Resource’s Iopanoic Acid Production Cost Reports Can Help

At Procurement Resource, we offer comprehensive Iopanoic Acid Production Cost Reports that provide businesses with a detailed analysis of the factors influencing production costs. Our reports are designed to give you a deeper understanding of where costs arise and offer insights into how to manage and optimise those expenses effectively. Here’s how our reports can benefit your business:

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/iopanoic-acid/ask-an-analyst

- Detailed Cost Breakdown: Our reports offer a comprehensive breakdown of the key cost components involved in Iopanoic acid production, from raw materials and energy to labor and compliance expenses.

- Real-Time Data: The pharmaceutical market is constantly evolving. Our reports provide up-to-date data and forecasts, allowing businesses to make informed decisions based on the latest trends and market conditions.

- Price Trends and Analysis: Understanding price trends for raw materials and energy is essential for forecasting production costs. Our reports track these trends, helping businesses plan for price fluctuations and optimise purchasing strategies.

- Benchmarking and Comparison: We provide industry benchmarks that allow you to compare your production costs with competitors, helping you identify areas for improvement and reduce unnecessary expenses.

- Procurement Insights: Our reports include actionable procurement insights, guiding you on how to optimise your supply chain and purchasing strategy to lower costs and improve efficiency.

Stay Ahead of Market Trends with Procurement Resource

By partnering with Procurement Resource, you’ll gain access to industry-leading insights that help you stay competitive in the Iopanoic acid market. Our reports provide valuable intelligence on production costs, raw material price trends, and regulatory factors, giving you the tools needed to optimise your production processes and manage procurement more effectively.

We understand that each business faces unique challenges, and our reports are customisable to meet your specific needs. Whether you are looking to reduce production costs, improve operational efficiency, or navigate complex regulatory environments, our team of expert analysts is here to support you.

Request Your Free Sample Report Today

If you’re ready to take control of your Iopanoic acid production costs and optimise your procurement strategies, we invite you to request a free sample report from Procurement Resource. Our reports will equip you with the knowledge and insights needed to manage your costs effectively and stay ahead in the competitive pharmaceutical industry.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/iopanoic-acid/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA copyright: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA