Parathion, a highly toxic organophosphate pesticide, has been widely used in agricultural settings for controlling pests on crops like fruits, cotton, and vegetables. Despite its efficacy, its hazardous nature has led to strict regulations regarding its use and production across the globe. Understanding the production cost of parathion is crucial for companies and industries involved in pesticide manufacturing. This report delves into the process of parathion production, examining the cost factors, raw materials, and manufacturing complexities that play a pivotal role in the overall expense.

Production Process

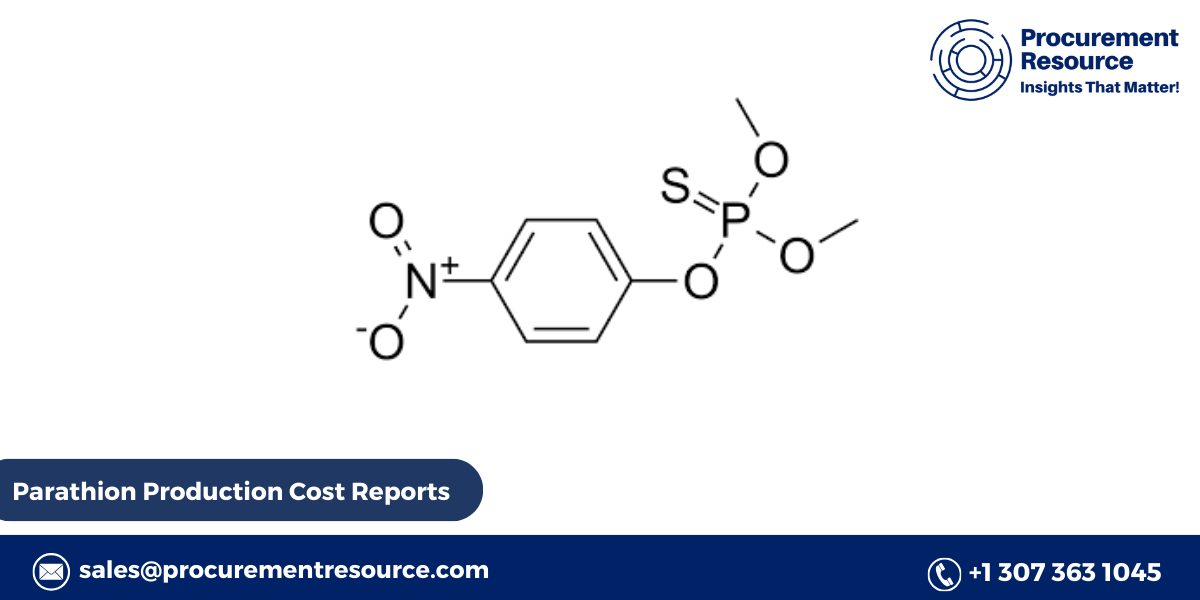

The production of parathion involves a multi-step chemical process that requires precise handling due to its toxic nature. Parathion is synthesized primarily through the reaction of diethyl dithiophosphoric acid with p-nitrophenol. This reaction creates O,O-Diethyl O-(4-nitrophenyl) phosphorothioate, commonly known as parathion.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/parathion/request-sample

Key stages of the production process include:

- Preparation of Raw Materials: The process starts with the preparation of key raw materials, such as diethyl phosphorochloridothioate and p-nitrophenol. These materials are purified and tested for quality before being used in the reaction.

- Chemical Synthesis: In a reactor, diethyl phosphorochloridothioate reacts with p-nitrophenol under controlled conditions to yield parathion. The reaction typically occurs in the presence of an acid catalyst to promote synthesis and ensure a high yield of the product.

- Purification: After the reaction, the crude parathion product undergoes purification processes such as distillation and filtration. This ensures the removal of impurities and unreacted raw materials.

- Quality Control and Testing: The final product is tested for quality control to meet safety standards and regulatory requirements. Given the toxicity of parathion, rigorous testing is essential before the product is packaged for distribution.

The overall process is complex and requires careful management of raw materials, safety protocols, and equipment, contributing to the overall production cost.

Manufacturing Report and Process

The manufacturing of parathion is highly regulated due to the compound’s toxicity and environmental impact. This necessitates specialized equipment, safety measures, and trained personnel to handle its production safely. The following factors impact the cost of the manufacturing process:

- Specialized Equipment: Parathion production requires the use of reactors, distillation columns, and filtration systems that can withstand the corrosive nature of the chemicals involved. The cost of maintaining and updating this equipment is a significant component of production costs.

- Safety and Environmental Controls: Given the hazardous nature of parathion, safety measures are crucial. This includes the installation of protective equipment, ventilation systems, and emergency protocols. Additionally, manufacturers must adhere to stringent environmental regulations, including the safe disposal of waste products, further increasing operational costs.

- Energy and Labor Costs: The chemical synthesis of parathion is energy-intensive. Factories require a steady energy supply to maintain the necessary temperatures and pressure conditions during the production process. Moreover, skilled labor is essential to ensure the process is handled safely, which adds to the labor costs.

- Compliance and Regulatory Costs: Manufacturers must comply with various international, national, and local regulations regarding the production and sale of parathion. These regulations often require extensive documentation, certifications, and regular inspections, all of which contribute to the cost of production.

The entire manufacturing process must be optimized to balance efficiency and safety while minimizing environmental impact and adhering to legal standards.

Raw Material Costs

The cost of raw materials is one of the most significant contributors to the overall cost of producing parathion. The primary raw materials used in the production of parathion include:

- Diethyl Phosphorochloridothioate: This organophosphate compound is a critical ingredient in parathion synthesis. The cost of sourcing, storing, and handling this material can fluctuate based on market demand and supply chain factors.

- p-Nitrophenol: Another essential raw material, p-nitrophenol, is often sourced from suppliers that specialize in high-purity chemicals. The price of p-nitrophenol may vary based on purity levels, availability, and transportation costs.

- Catalysts and Additives: To speed up the chemical reaction and improve yields, catalysts are used during production. These catalysts are typically expensive and need to be replenished regularly, adding to the overall production cost.

- Solvents and Purification Agents: Solvents such as ethanol or acetone are used to purify and process parathion during manufacturing. These solvents are consumed in large quantities and must be regularly replaced, impacting the cost.

- Energy and Utilities: The energy required to run reactors, purification systems, and other equipment is a significant cost component. Energy prices can fluctuate depending on the region and energy source, adding to production unpredictability.

Any fluctuation in the prices of these raw materials directly impacts the cost of parathion production, making it essential for manufacturers to monitor market trends and secure stable suppliers.

Latest News

The production and use of parathion have faced increasing scrutiny in recent years due to its environmental impact and toxic effects on human health. Regulatory bodies worldwide, such as the United States Environmental Protection Agency (EPA) and the European Union, have either banned or restricted the use of parathion, pushing manufacturers to explore safer alternatives or improve production processes to meet modern safety standards.

- Shift Towards Safer Alternatives: In response to growing environmental and health concerns, some manufacturers are focusing on developing less toxic alternatives to parathion. This shift has also resulted in increased research and development costs for companies attempting to innovate within the pesticide industry.

- Regulatory Changes: Several countries have introduced new regulations that limit or completely ban the production and sale of parathion. In regions where parathion production is still permitted, manufacturers must adhere to stricter guidelines, increasing the cost of compliance.

- Environmental Impact Initiatives: There has been a growing focus on reducing the environmental impact of pesticide production, including parathion. This has led to the adoption of more sustainable production practices, such as the reduction of waste by-products, eco-friendly disposal methods, and recycling of solvents and catalysts.

- Global Supply Chain Challenges: The recent global supply chain disruptions have impacted the availability of raw materials used in the production of parathion. Manufacturers are now exploring local suppliers to reduce dependency on international markets, which may lead to cost variations.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.procurementresource.com/