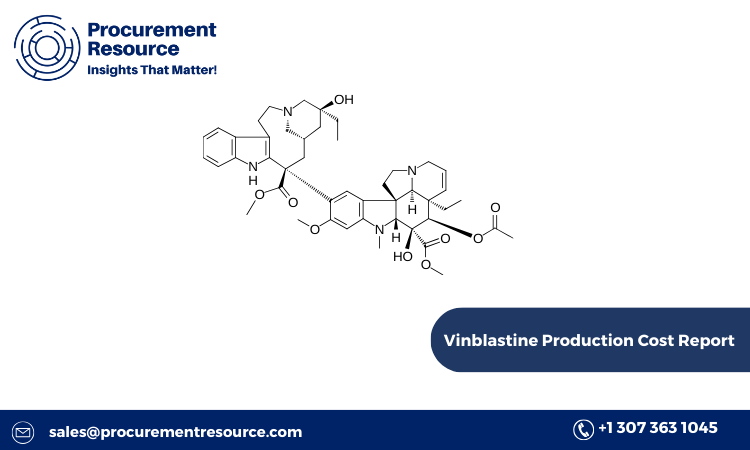

Vinblastine, an alkaloid derived from the Madagascar periwinkle plant, is a critical chemotherapeutic agent used primarily in the treatment of various types of cancer, including Hodgkin’s lymphoma, breast cancer, and testicular cancer. The cost of producing vinblastine is influenced by multiple factors, including the availability and cost of raw materials, the complexity of the extraction and synthesis processes, and the scale of production. Understanding the intricacies of Vinblastine production is crucial for pharmaceutical companies aiming to optimize their manufacturing processes and reduce costs while ensuring a consistent supply of this vital drug.

Production Process

The production process of vinblastine is complex and involves multiple stages, each of which contributes to the overall cost. The initial step in Vinblastine production is the extraction of vinca alkaloids from the leaves of the Catharanthus roseus plant (commonly known as Madagascar periwinkle). The plant material undergoes a series of extraction processes to isolate the alkaloids, including Vinblastine.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/vinblastine/request-sample

- Plant Cultivation and Harvesting: The first stage in the production process involves the cultivation of Catharanthus roseus. The plant requires specific growing conditions, including a warm climate, well-drained soil, and adequate water supply. After reaching maturity, the leaves are harvested, dried, and prepared for the extraction process.

- Alkaloid Extraction: The dried leaves are subjected to a solvent extraction process, where organic solvents like methanol or ethanol are used to extract the alkaloids from the plant material. The solvent is then evaporated, leaving behind a crude extract that contains a mixture of various alkaloids, including Vinblastine.

- Isolation and Purification: The crude extract undergoes further purification through chromatography techniques, such as high-performance liquid chromatography (HPLC) or column chromatography. These methods help isolate Vinblastine from other alkaloids present in the extract.

- Synthesis and Conversion: In some cases, additional chemical synthesis may be required to convert the isolated alkaloid into Vinblastine. This step often involves complex organic chemistry techniques and is a crucial part of the production process.

- Formulation: The final stage of Vinblastine production involves formulating the purified alkaloid into a suitable pharmaceutical form, such as injectable solutions. This step requires strict adherence to quality control standards to ensure the safety and efficacy of the drug.

Manufacturing Report and Process

The manufacturing report for vinblastine provides a detailed overview of the entire production process, from the cultivation of Catharanthus roseus to the final formulation of the drug. The report includes information on the equipment and technology used in each stage of production, as well as the labor and energy costs associated with the process.

- Equipment and Technology: The extraction and purification of Vinblastine require specialized equipment, including solvent extraction units, chromatography columns, and synthesis reactors. The choice of equipment can significantly impact production efficiency and cost. For instance, using advanced chromatography techniques can improve the purity of the final product, reducing the need for additional purification steps.

- Labor and Expertise: The production of Vinblastine is labor-intensive and requires skilled personnel with expertise in organic chemistry, pharmaceutical manufacturing, and quality control. Labor costs are a significant component of the overall production cost, particularly in the isolation and purification stages.

- Quality Control and Compliance: Given the critical nature of Vinblastine as a cancer treatment, strict quality control measures are essential throughout the manufacturing process. This includes regular testing of raw materials, intermediates, and the final product to ensure compliance with pharmaceutical standards. The costs associated with quality control, including laboratory testing and regulatory compliance, are factored into the overall production cost.

- Scale of Production: The scale at which Vinblastine is produced also influences the cost. Large-scale production may benefit from economies of scale, reducing the per-unit cost of the drug. However, scaling up production requires significant capital investment in equipment and facilities, which must be balanced against potential cost savings.

Raw Material Costs

The cost of raw materials is one of the most significant factors influencing the overall cost of Vinblastine production. The primary raw material, Catharanthus roseus, must be cultivated and harvested under specific conditions, which can be affected by environmental factors such as climate and soil quality. Additionally, the yield of alkaloids from the plant can vary, impacting the efficiency of the extraction process.

- Catharanthus Roseus: The cost of cultivating and harvesting Catharanthus roseus is influenced by factors such as land availability, agricultural practices, and labor costs. In regions where the plant is not native, additional costs may be incurred for importing seeds or establishing cultivation facilities.

- Solvents and Chemicals: The extraction and purification of Vinblastine require the use of organic solvents and other chemicals, which contribute to the raw material costs. The price of these chemicals can fluctuate based on market demand and availability, affecting the overall production cost.

- Energy Costs: The extraction and purification processes are energy-intensive, requiring significant amounts of electricity and heat. Energy costs can vary depending on the location of the manufacturing facility and the efficiency of the equipment used.

- Waste Management: The production of Vinblastine generates waste materials, including spent plant material and solvent residues. Proper disposal and management of these waste materials are necessary to comply with environmental regulations, adding to the raw material costs.

Latest News

The production of Vinblastine and other vinca alkaloids has seen several developments in recent years, particularly in the areas of sustainability and cost reduction. Researchers are exploring alternative methods for producing Vinblastine, such as synthetic biology and plant cell culture techniques, which could potentially reduce dependence on Catharanthus roseus and lower production costs.

- Synthetic Biology: Advances in synthetic biology have opened up new possibilities for producing Vinblastine through microbial fermentation. By engineering bacteria or yeast to produce Vinblastine precursors, it may be possible to bypass the need for plant cultivation and extraction altogether. This approach could significantly reduce the cost and environmental impact of Vinblastine production.

- Plant Cell Culture: Another promising area of research involves the use of plant cell cultures to produce Vinblastine. By cultivating Catharanthus roseus cells in bioreactors, researchers can potentially produce alkaloids in a controlled environment, improving yields and reducing variability. This method also offers the advantage of year-round production, independent of agricultural cycles.

- Market Dynamics: The global demand for Vinblastine is expected to increase in the coming years, driven by rising cancer incidence rates and expanding access to healthcare in developing regions. Pharmaceutical companies are investing in new production facilities and technologies to meet this demand while controlling costs.

- Regulatory Changes: Changes in regulatory requirements, particularly related to environmental sustainability, are also impacting the Vinblastine production industry. Companies are being encouraged to adopt greener production methods and reduce their carbon footprint, which may lead to additional investments in research and development.

In conclusion, understanding the production process, manufacturing complexities, raw material costs, and staying updated with the latest industry developments is essential for optimizing Vinblastine production. As the industry continues to evolve, advancements in technology and sustainable practices will play a crucial role in shaping the future of Vinblastine manufacturing.