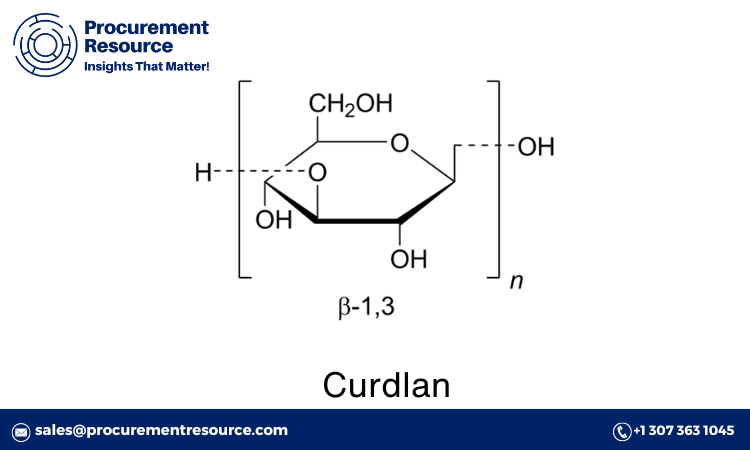

Curdlan, a polysaccharide produced by bacteria, is renowned for its unique gel-forming properties, making it valuable in various industrial applications, particularly in the food and pharmaceutical industries. Understanding the production cost of curdlan is crucial for businesses and researchers aiming to optimize its manufacturing process and explore its potential uses. This report delves into the intricacies of curdlan production, examining the costs associated with its production process, raw materials, and recent developments in the industry.

Production Process

Curdlan production involves a series of biological and chemical processes primarily executed by certain strains of bacteria, such as Agrobacterium and Alcaligenes. The production process can be broken down into several key stages:

Request For Sample: https://www.procurementresource.com/production-cost-report-store/curdlan/request-sample

- Inoculum Preparation: The process begins with the preparation of the bacterial inoculum. The selected bacterial strain is cultured in a nutrient-rich medium to ensure robust growth and high polysaccharide yield.

- Fermentation: The inoculum is then transferred to a fermenter, where it undergoes aerobic fermentation. During this stage, the bacteria convert the carbon source (often glucose) into curdlan. Key factors such as pH, temperature, and aeration are meticulously controlled to maximize curdlan production.

- Recovery and Purification: After fermentation, the curdlan must be separated from the bacterial cells and other fermentation by-products. This is typically achieved through centrifugation and filtration processes. The crude curdlan is then subjected to further purification steps, including precipitation, washing, and drying, to obtain the final product.

- Drying and Packaging: The purified curdlan is dried to a specific moisture content and then packaged for distribution. The drying method, whether it be spray drying or freeze-drying, can significantly influence the quality and cost of the final product.

Manufacturing Report and Process

A comprehensive manufacturing report on curdlan production would cover the following aspects:

- Plant Layout and Design: Detailed schematics of the production facility, including the placement of fermenters, centrifuges, filtration units, and drying equipment.

- Equipment and Machinery: Specifications and costs associated with the necessary equipment, such as fermenters, centrifuges, filtration systems, and dryers. This section would also include maintenance and operational costs.

- Production Capacity and Scalability: Analysis of the current production capacity and potential scalability of the process. This includes evaluating the feasibility of expanding production to meet increasing demand.

- Quality Control and Assurance: Procedures and protocols to ensure the quality and consistency of curdlan. This includes testing for purity, viscosity, and gel strength, as well as adherence to regulatory standards.

- Environmental and Safety Considerations: Measures to minimize environmental impact and ensure the safety of workers. This may involve waste management strategies, emission controls, and adherence to occupational health and safety regulations.

Raw Material Costs

The cost of raw materials is a significant factor in determining the overall production cost of curdlan. Key raw materials include:

- Carbon Source: Glucose is the primary carbon source for curdlan production. The cost of glucose can vary depending on its source (e.g., corn, sugarcane) and market fluctuations.

- Nutrient Medium: The bacterial growth medium must contain essential nutrients such as nitrogen, phosphorus, and trace elements. The composition and cost of the nutrient medium can impact the efficiency and yield of curdlan production.

- Utilities: The production process requires significant amounts of energy and water. The cost of electricity, water, and other utilities must be factored into the overall production cost.

- Labor and Overhead: Skilled labor is essential for managing and optimizing the production process. Labor costs, along with overhead expenses such as facility maintenance and administrative costs, contribute to the total production cost.

Latest News

Keeping abreast of the latest developments in curdlan production and the broader industry is essential for staying competitive. Recent news and trends include:

- Technological Advancements: Innovations in fermentation technology, such as the development of high-yield bacterial strains and optimized fermentation conditions, can significantly reduce production costs and increase curdlan yield.

- Market Demand and Applications: The growing demand for natural and functional food ingredients is driving the market for curdlan. New applications in the food, pharmaceutical, and biomedical sectors are expanding the market potential for curdlan.

- Regulatory Changes: Changes in regulatory frameworks, particularly concerning food additives and biopolymers, can impact the production and marketing of curdlan. Staying informed about regulatory updates is crucial for compliance and market access.

- Sustainability Initiatives: There is a growing emphasis on sustainable production practices. Efforts to reduce the environmental impact of curdlan production, such as using renewable energy sources and minimizing waste, are gaining traction.

- Collaborations and Partnerships: Collaborations between academic institutions, research organizations, and industry players are fostering innovation in curdlan production. Joint ventures and partnerships can lead to the development of cost-effective and efficient production methods.

Conclusion

In conclusion, the production cost of curdlan is influenced by various factors, including the production process, raw material costs, and recent industry developments. By understanding these elements, businesses can optimize their production strategies, reduce costs, and capitalize on the growing market demand for curdlan. As technological advancements and sustainability initiatives continue to shape the industry, staying informed about the latest trends and innovations will be crucial for success in curdlan production.