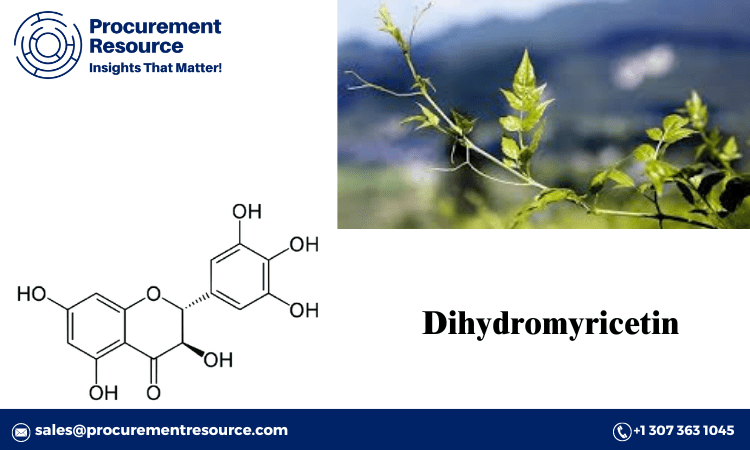

Dihydromyricetin (DHM), also known as ampelopsin, is a flavonoid compound primarily found in the Japanese raisin tree (Hovenia dulcis). Over the years, DHM has garnered significant attention due to its potential health benefits, including anti-alcohol intoxication effects, liver protection, and anti-inflammatory properties. With the rising interest in natural health supplements and functional foods, the production of DHM has seen a notable increase. This report delves into the production process, the associated costs of raw materials, and the latest news in the DHM industry.

Manufacturing Report and Process

The production of Dihydromyricetin involves several key steps, each critical to ensuring the purity and efficacy of the final product. The process can be broadly divided into extraction, purification, and drying.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/dihydromyricetin-dhm/request-sample

- Extraction:

- Source Material: The primary source for DHM is the Hovenia dulcis plant. The leaves and stems of this plant are harvested and dried before processing.

- Solvent Extraction: The dried plant material is subjected to solvent extraction using ethanol or methanol. This step involves soaking the plant material in the solvent, which helps dissolve the DHM and other soluble compounds.

- Filtration: The resulting solution is filtered to remove solid plant residues, leaving behind a crude DHM extract in the solvent.

- Purification:

- Liquid-Liquid Extraction: The crude extract undergoes liquid-liquid extraction to separate DHM from other compounds. This step may involve using different solvents to selectively isolate DHM.

- Column Chromatography: Further purification is achieved through column chromatography, where the DHM is separated based on its chemical properties. This method ensures a high purity level of DHM in the final product.

- Drying:

- Evaporation: The purified DHM solution is subjected to evaporation to remove the solvent. This step is crucial to obtain DHM in its solid form.

- Spray Drying or Freeze Drying: The concentrated DHM is then dried using either spray drying or freeze drying. Spray drying involves spraying the solution into a hot chamber, where the solvent evaporates, leaving behind fine DHM powder. Freeze drying, on the other hand, involves freezing the solution and then sublimating the solvent under vacuum, resulting in a dry powder.

The entire manufacturing process is designed to maximize yield and purity while minimizing environmental impact and production costs. Continuous advancements in extraction and purification technologies are further enhancing the efficiency and scalability of DHM production.

Raw Material Costs

The cost of raw materials is a significant factor in the overall economics of DHM production. Key cost components include:

- Hovenia dulcis Plant:

- The availability and cost of Hovenia dulcis plant material can vary based on the region and season. Cultivating the plant in controlled environments or sourcing from reliable suppliers can help stabilize costs.

- Solvents:

- Ethanol and methanol are commonly used solvents in the extraction process. The cost of these solvents can fluctuate based on market demand and supply. Efficient solvent recovery and recycling practices can help mitigate these costs.

- Labor and Equipment:

- Skilled labor is essential for managing the extraction and purification processes. The cost of labor can vary depending on the location of the production facility. Additionally, investment in high-quality extraction and purification equipment is necessary to ensure efficient production and high product quality.

- Energy:

- Energy costs, particularly for drying processes such as spray drying or freeze drying, can be substantial. Implementing energy-efficient technologies and practices can help reduce these expenses.

- Packaging and Logistics:

- The final DHM product must be packaged in a manner that ensures its stability and shelf life. Packaging materials and logistics costs, including transportation and storage, also contribute to the overall production costs.

Latest News

The Dihydromyricetin industry is continually evolving, with new research, technological advancements, and market developments shaping its trajectory. Some of the latest news and trends include:

- Research and Development:

- Recent studies have explored the potential of DHM in treating a variety of health conditions, including its neuroprotective effects and its role in mitigating alcohol-related liver damage. Ongoing research aims to uncover new therapeutic applications and enhance the bioavailability of DHM.

- Technological Innovations:

- Innovations in extraction and purification technologies are improving the efficiency and sustainability of DHM production. For example, advancements in supercritical fluid extraction and membrane filtration techniques are reducing the environmental impact and operational costs of the production process.

- Market Expansion:

- The demand for natural health supplements is driving the expansion of the DHM market. Consumers are increasingly seeking natural alternatives for liver health, hangover prevention, and overall wellness. This trend is prompting manufacturers to explore new product formulations and expand their distribution channels.

- Regulatory Developments:

- Regulatory agencies in various countries are establishing guidelines for the production and marketing of DHM supplements. Compliance with these regulations is essential for manufacturers to ensure product safety and quality. Recent regulatory changes may also impact the labeling, advertising, and distribution of DHM products.

- Collaborations and Partnerships:

- Companies in the DHM industry are forming strategic collaborations and partnerships to enhance their research capabilities and market reach. These collaborations can facilitate the development of new DHM-based products and improve access to raw materials and advanced technologies.

- Consumer Awareness:

- Increasing consumer awareness about the benefits of DHM is driving market growth. Educational campaigns and marketing initiatives are helping to inform consumers about the potential health benefits of DHM, contributing to higher demand and market penetration.

Conclusion

Dihydromyricetin production is a complex process that involves meticulous extraction, purification, and drying steps to ensure the highest quality product. The costs associated with raw materials, labor, equipment, energy, and logistics are significant factors influencing the overall economics of production. However, advancements in technology and strategic market developments are paving the way for more efficient and sustainable DHM production.

As research continues to uncover new health benefits and applications for DHM, the industry is poised for further growth. Regulatory developments, technological innovations, and increasing consumer awareness are all contributing to the dynamic landscape of the DHM market. By staying abreast of these trends and developments, stakeholders in the DHM industry can navigate challenges and capitalize on emerging opportunities.