Boron carbide (B4C) is a highly durable ceramic material known for its exceptional hardness and chemical resistance. It’s extensively used in applications requiring high durability, such as ballistic armor, cutting tools, and abrasives. Understanding the production costs of boron carbide is essential for manufacturers and stakeholders to optimize processes and enhance profitability. This report provides a detailed analysis of the various cost components involved in the production of boron carbide, including manufacturing processes, raw material expenses, and the latest market developments.

Manufacturing Report and Process

The production of boron carbide involves several intricate steps, each contributing to the overall cost. The primary methods for producing boron carbide are the carbothermic reduction of boron oxide (B2O3) in an electric arc furnace or the direct reaction of boron and carbon at high temperatures. Below is an overview of the typical manufacturing process:

Request For Sample: https://www.procurementresource.com/production-cost-report-store/boron-carbide/request-sample

- Raw Material Preparation:

- Boron oxide (B2O3) and carbon (typically in the form of petroleum coke) are the primary raw materials used.

- These materials must be of high purity to ensure the quality of the final product.

- Mixing:

- The boron oxide and carbon are mixed in specific proportions to achieve the desired stoichiometry of B4C.

- Mixing is done in high-intensity mixers to ensure uniform distribution of the materials.

- Reduction Reaction:

- The mixed materials are fed into an electric arc furnace where they are heated to temperatures above 2000°C.

- In the furnace, a carbothermic reduction reaction occurs, producing boron carbide and carbon monoxide (CO) gas.

- The reaction is highly exothermic and requires careful temperature control.

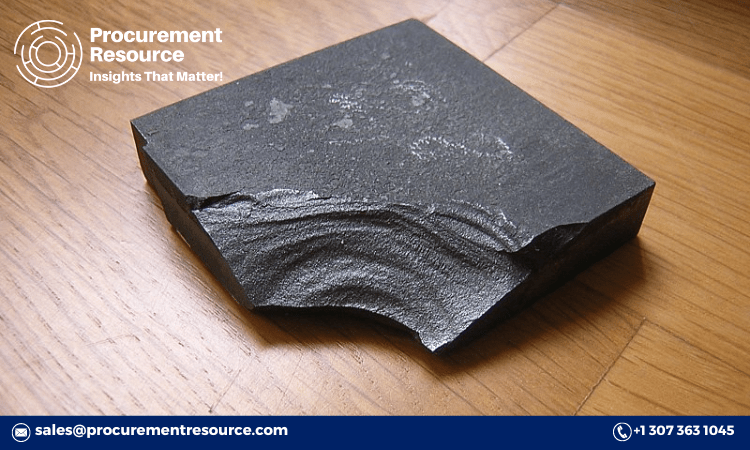

- Cooling and Crushing:

- The hot boron carbide is allowed to cool slowly in the furnace to prevent thermal cracking.

- Once cooled, the solidified boron carbide is crushed and milled into powder or granules of the desired particle size.

- Purification:

- Depending on the application, additional purification steps may be required to remove impurities.

- Techniques such as acid leaching or high-temperature treatment can be used to achieve the required purity levels.

- Sintering (if needed):

- For some applications, boron carbide is further processed by sintering to form dense, solid shapes.

- Sintering involves pressing the powder into molds and heating it to high temperatures to promote particle bonding without melting.

Each of these steps involves specific costs related to energy consumption, equipment, labor, and maintenance. Optimizing these processes can significantly impact the overall production cost of boron carbide.

Raw Material Costs

The cost of raw materials is a significant component of the overall production cost of boron carbide. The primary raw materials include:

- Boron Oxide (B2O3):

- Boron oxide is typically sourced from borate minerals such as colemanite and ulexite.

- The price of boron oxide can vary based on purity levels and market demand.

- As of recent market data, the average cost of boron oxide ranges between $1,000 to $1,500 per metric ton.

- Carbon:

- Petroleum coke is the preferred source of carbon due to its high carbon content and low impurities.

- The cost of petroleum coke is influenced by factors such as crude oil prices and availability.

- On average, petroleum coke costs around $200 to $300 per metric ton.

- Energy:

- The electric arc furnace used in the production process is highly energy-intensive.

- Energy costs can vary significantly depending on the location and energy source.

- Typically, energy costs can account for up to 20-30% of the total production cost.

- Labor:

- Skilled labor is required to operate and maintain the equipment used in boron carbide production.

- Labor costs can vary based on the region and the level of automation in the production facility.

Latest News

Staying updated with the latest developments in the boron carbide industry is crucial for manufacturers and investors. Here are some recent trends and news highlights:

- Advancements in Manufacturing Technology:

- Recent advancements in manufacturing technologies, such as improved electric arc furnaces and automated control systems, are helping reduce production costs and improve efficiency.

- Companies are investing in research and development to develop cost-effective methods for producing high-purity boron carbide.

- Growing Demand in Defense Sector:

- The increasing demand for lightweight, durable materials in the defense sector is driving the growth of the boron carbide market.

- Boron carbide’s exceptional hardness makes it an ideal material for ballistic armor and protective equipment.

- Environmental Regulations:

- Stricter environmental regulations are influencing the production processes in the chemical industry.

- Manufacturers are adopting cleaner and more sustainable production methods to comply with environmental standards and reduce carbon footprints.

- Market Expansion in Asia-Pacific:

- The Asia-Pacific region, particularly China and India, is emerging as a significant market for boron carbide.

- Increased industrial activities and investments in infrastructure are boosting the demand for boron carbide in this region.

- Strategic Collaborations and Acquisitions:

- Companies are engaging in strategic collaborations and acquisitions to strengthen their market position and expand their product offerings.

- For example, recent mergers between leading boron carbide producers are aimed at enhancing production capacities and achieving economies of scale.

Conclusion

The production cost of boron carbide is influenced by various factors, including raw material prices, energy consumption, and manufacturing processes. Understanding these cost components and staying updated with the latest industry developments can help manufacturers optimize their operations and remain competitive in the market. With growing demand from sectors like defense and increasing investments in manufacturing technologies, the boron carbide industry is poised for significant growth in the coming years. By focusing on cost-effective production methods and sustainable practices, companies can capitalize on the opportunities in this dynamic market.