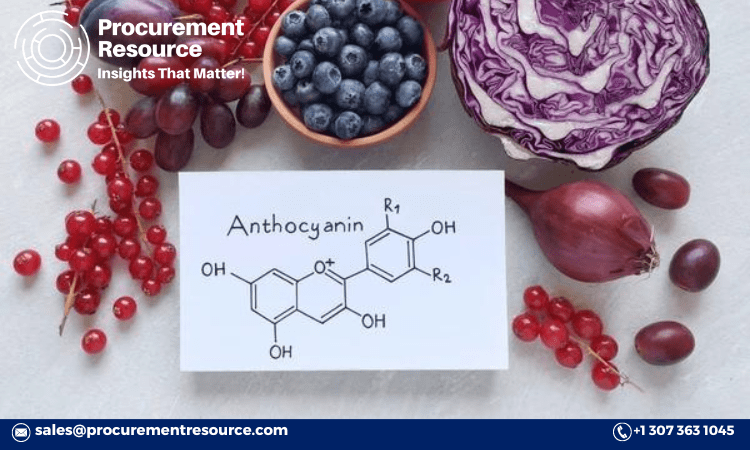

Anthocyanins are water-soluble pigments that belong to the flavonoid group and are responsible for the red, purple, and blue colors in many fruits and vegetables. These pigments are not only valued for their vibrant colors but also for their antioxidant properties and potential health benefits. The production of anthocyanins on an industrial scale involves a meticulous process to ensure high yield and quality, catering to the increasing demand from food, pharmaceutical, and cosmetic industries.

Manufacturing Report and Process

1. Raw Material Selection

The first step in the anthocyanin production process is the selection of raw materials. Common sources include fruits such as blueberries, blackberries, raspberries, and grapes, as well as vegetables like red cabbage and purple sweet potatoes. The choice of raw material depends on the desired type of anthocyanin, the cost, and the availability.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/anthocyanin/request-sample

2. Extraction

The extraction of anthocyanins typically involves using solvents to separate the pigment from the plant material. Ethanol, methanol, and water are commonly used solvents. The plant material is usually crushed and mixed with the solvent, followed by a process called maceration, where the mixture is allowed to stand, facilitating the release of anthocyanins into the solvent.

3. Filtration and Purification

After extraction, the mixture undergoes filtration to remove solid residues, leaving behind a liquid extract rich in anthocyanins. The next step is purification, which involves techniques like chromatography. High-performance liquid chromatography (HPLC) is frequently used to purify anthocyanins by separating them based on their chemical properties.

4. Concentration and Drying

The purified anthocyanin extract is then concentrated using methods such as vacuum evaporation. This step is crucial to reduce the volume of the extract and increase the concentration of anthocyanins. The concentrated extract can be further processed into powder form through spray drying or freeze drying, making it easier to handle, store, and incorporate into various products.

5. Quality Control

Quality control is a critical component throughout the production process. Analytical methods such as UV-Vis spectroscopy and HPLC are used to determine the concentration and purity of anthocyanins. Additionally, microbial testing ensures that the product is free from contaminants, adhering to industry standards and regulations.

Raw Material Costs

The cost of raw materials for anthocyanin production can vary significantly based on several factors, including the type of plant source, geographic location, and seasonality. Here is a brief overview of cost considerations for some common sources:

1. Fruits and Vegetables

- Berries (e.g., blueberries, blackberries): The cost of berries can fluctuate based on seasonal availability and geographic location. On average, the cost of berries ranges from $2 to $6 per pound.

- Grapes: Grapes are another major source of anthocyanins. Their cost varies depending on the variety and region, averaging around $1.5 to $3 per pound.

- Red Cabbage and Purple Sweet Potatoes: These vegetables are often less expensive than fruits, typically costing between $0.5 to $2 per pound.

2. Agricultural Practices

The cost of raw materials is also influenced by agricultural practices. Organic farming methods, which avoid synthetic pesticides and fertilizers, can result in higher costs compared to conventional farming. However, organic products are often preferred for their perceived health benefits and lower environmental impact.

3. Supply Chain

The efficiency of the supply chain, including transportation and storage, plays a crucial role in determining raw material costs. Fresh produce needs to be handled carefully to prevent spoilage, which can add to the overall cost. Additionally, fluctuations in fuel prices and labor costs can impact the final price of raw materials.

Latest News

1. Technological Advancements

Recent advancements in extraction technologies are significantly impacting the anthocyanin production process. Techniques like supercritical fluid extraction (SFE) and ultrasonic-assisted extraction (UAE) are gaining popularity due to their efficiency and environmental benefits. These methods not only improve the yield and purity of anthocyanins but also reduce the use of harmful solvents, making the production process more sustainable.

2. Market Growth and Trends

The global demand for anthocyanins is on the rise, driven by the growing awareness of their health benefits and their application in various industries. According to recent market reports, the anthocyanin market is expected to witness substantial growth over the next few years. This growth is attributed to the increasing use of natural colorants in the food and beverage industry, as well as the rising demand for dietary supplements and cosmetics.

3. Research and Development

Ongoing research and development are focused on exploring new sources of anthocyanins and improving extraction and purification techniques. Scientists are also investigating the potential health benefits of anthocyanins, including their role in preventing chronic diseases such as cardiovascular diseases and cancer. These studies are likely to further boost the demand for anthocyanins and expand their applications.

4. Regulatory Updates

Regulatory bodies around the world are increasingly recognizing the importance of natural colorants and antioxidants like anthocyanins. Recent updates in food safety and labeling regulations are encouraging the use of natural ingredients, which is expected to drive the market for anthocyanins. Compliance with these regulations ensures that the products meet safety standards and are free from harmful contaminants.

Conclusion

The production of anthocyanins involves a detailed and well-regulated process to ensure high quality and yield. From raw material selection to advanced extraction and purification techniques, each step plays a crucial role in producing these valuable pigments. With technological advancements and growing market demand, the future of anthocyanin production looks promising, offering numerous opportunities for innovation and growth in various industries.