In the dynamic world of chemical production, understanding the intricacies of cost analysis is crucial for businesses aiming to optimize their operations and maximize profitability. At Procurement Resource, we delve deep into the Meta Xylene production cost processes, providing comprehensive insights and detailed cost analysis that empowers businesses to make informed decisions.

Procurement Resource Assessment of Meta Xylene Production Process

Our meticulous assessment of the Meta Xylene production process encompasses a thorough examination of each step involved, from raw material acquisition to the final product output. By evaluating the production techniques and the associated costs, we offer a clear picture of the financial landscape that businesses navigate. Our assessment includes an in-depth analysis of capital investments, operational expenditures, and variable costs, ensuring a holistic view of the production process.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/meta-xylene/request-sample

Product Definition of Meta Xylene

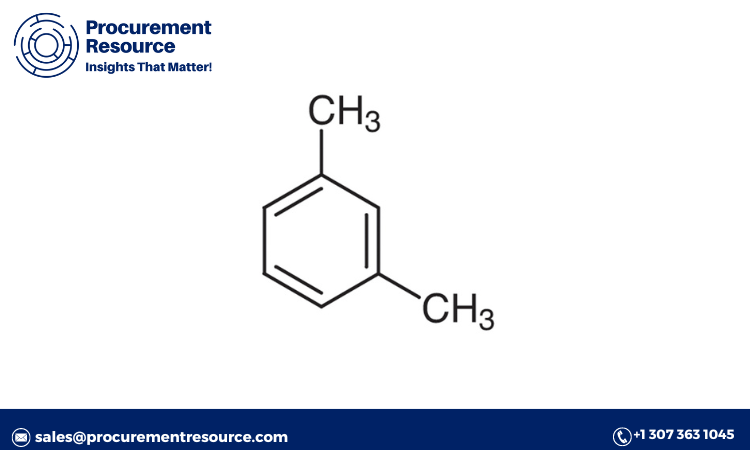

Meta Xylene, an aromatic hydrocarbon, is a crucial intermediate used in the manufacturing of various chemical products. It is one of the three isomers of xylene, the others being ortho-xylene and para-xylene. Meta Xylene is primarily employed in the production of isophthalic acid, which is an essential component in the manufacturing of PET (polyethylene terephthalate) resin. It is also used in the production of dyes, coatings, and other specialty chemicals. Due to its versatile applications, Meta Xylene plays a vital role in several industrial sectors.

Market Drivers of Meta Xylene

The demand for Meta Xylene is driven by several key factors:

- Growing PET Resin Demand: The increasing demand for PET resin, used in packaging materials, bottles, and textiles, significantly boosts the consumption of Meta Xylene.

- Expansion of the Chemical Industry: The broadening applications of Meta Xylene in various chemical processes and the continuous innovation in chemical manufacturing spur its market growth.

- Rising Demand in Paints and Coatings: The use of Meta Xylene in the production of high-quality paints and coatings contributes to its steady market demand.

- Emerging Markets: The industrial growth in emerging markets, particularly in Asia-Pacific, where rapid industrialization and urbanization are prevalent, is a major driver for Meta Xylene demand.

Product Details

Meta Xylene, chemically known as 1,3-dimethylbenzene, is produced through various methods, including catalytic reforming, toluene disproportionation, and methanol-to-aromatics (MTA) process. Each production method has its unique cost implications and efficiency parameters. The choice of production method largely depends on the availability of raw materials, desired product purity, and specific industrial requirements.

Key Questions

Our detailed cost analysis report on Meta Xylene addresses several critical questions that businesses often encounter:

- What are the primary cost components in the Meta Xylene production process?

- How do different production methods impact the overall cost structure?

- What are the key factors influencing raw material costs?

- How do energy and utility costs affect production economics?

- What are the capital expenditure requirements for setting up a Meta Xylene production facility?

- How do market dynamics and supply chain factors influence the cost of Meta Xylene production?

Latest News and Update

The Meta Xylene market is continuously evolving, with significant developments influencing its production and cost dynamics:

- Technological Advancements: Recent advancements in catalytic reforming and methanol-to-aromatics (MTA) processes have led to more efficient production techniques, reducing overall costs and improving output quality.

- Sustainability Initiatives: The industry is witnessing a shift towards more sustainable production methods, with an emphasis on reducing carbon footprint and enhancing energy efficiency.

- Market Expansion: The Asia-Pacific region continues to dominate the Meta Xylene market, with new production facilities being established to cater to the growing demand in China, India, and Southeast Asia.

- Regulatory Changes: Environmental regulations and policies are shaping the production landscape, prompting companies to adopt cleaner technologies and adhere to stringent emission norms.

- Supply Chain Disruptions: The global supply chain landscape has been impacted by various factors, including geopolitical tensions and the COVID-19 pandemic, affecting the availability of raw materials and production costs.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

At Procurement Resource, we understand that each business has unique needs and challenges. Our team of experts is dedicated to providing tailored solutions that address specific business requirements. Our exhaustive and personalized reports are designed to offer actionable insights and strategic recommendations that can significantly enhance your business operations and profitability.

Some of the common requests we receive from our clients include:

- Cost Optimization Strategies: Businesses seek our expertise to identify cost-saving opportunities within their production processes.

- Market Entry Analysis: Companies looking to enter the Meta Xylene market rely on our detailed reports to understand the competitive landscape and market dynamics.

- Investment Feasibility Studies: Investors and stakeholders leverage our cost analysis reports to evaluate the feasibility and potential returns of investing in Meta Xylene production.

- Supply Chain Analysis: Our comprehensive reports provide insights into the supply chain intricacies, helping businesses streamline their procurement and logistics operations.

- Environmental Impact Assessments: With growing emphasis on sustainability, companies turn to us for detailed assessments of the environmental impact of their production processes and strategies for mitigation.

Conclusion

In conclusion, our Meta Xylene Production Cost Analysis Report offers a detailed and insightful examination of the production process, cost components, and market dynamics. At Procurement Resource, we are committed to delivering high-quality, data-driven reports that empower businesses to make informed decisions. Whether you are looking to optimize your production costs, explore new market opportunities, or enhance your supply chain efficiency, our expert team is here to support you with comprehensive analysis and tailored solutions.