The latest report titled “Diisobutylene Production” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Diisobutylene.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/diisobutylene/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Diisobutylene production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Diisobutylene Production Process:

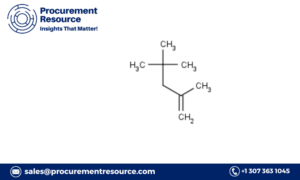

- From Dimerization Reaction: This report presents the detailed production methodology and cost analysis of Diisobutylene industrial production across Diisobutylene manufacturing plants. The process begins with the catalytic dimerization of isobutylene, involving the combination of two isobutylene molecules in the presence of an acid catalyst. Solid phosphoric acid is employed to facilitate this reaction, leading to the creation of diisobutylene as the end product.

Request For Free Sample: https://www.procurementresource.com/cost-analysis/diisobutylene-production-by-dimerization-reaction/requestsample

Product Definition:

Diisobutylene, a chemical compound with a formula generally represented as C8H16, is a type of hydrocarbon known for its role in various industrial applications. It is characterized by the dimerization of isobutylene, resulting in a molecule that combines two isobutylene units. This process, often catalyzed by acids such as phosphoric acid, leads to a compound that is valuable in the production of additives for fuels and lubricants, polymers, and as an intermediate in the synthesis of other chemicals. Its unique properties, including stability and reactivity, make it a versatile component in the chemical industry.

Market Drivers:

The market drivers for diisobutylene can be attributed to various factors:

- Automotive Industry: The primary driver for diisobutylene demand is the automotive industry. With the continuous growth in the automotive sector globally, especially in emerging economies, there’s a consistent demand for higher octane fuels to meet emission standards and improve engine performance. Diisobutylene serves this purpose effectively as an octane booster.

- Stringent Fuel Standards: Regulatory bodies across the world are imposing stricter emission norms, pushing the automotive industry to adopt cleaner-burning fuels. This drives the demand for additives like diisobutylene that can improve fuel quality and performance while meeting these standards.

- Growing Demand for High-Performance Fuels: As consumer preferences shift towards high-performance vehicles, there’s a consequent rise in the demand for high-octane fuels. Diisobutylene is crucial in formulating these fuels, making it a key component in meeting the demands of performance-oriented consumers.

- Expansion of Refining Industry: The expansion and modernization of refineries globally contribute to the increased production of gasoline and other refined products. With the rise in gasoline production, the demand for octane boosters like diisobutylene also increases.

- Economic Growth: Economic growth, particularly in developing regions, leads to increased vehicle ownership and consequently higher fuel consumption. This drives the demand for fuel additives like diisobutylene to improve fuel quality and performance.

- Research and Development: Ongoing research and development efforts aimed at enhancing fuel efficiency and reducing emissions also contribute to the demand for additives like diisobutylene. As new technologies and formulations are developed, the demand for high-performance additives is likely to increase.

- Substitute Demand: As regulations evolve and environmental concerns become more pronounced, the demand for alternative fuel additives may arise. However, diisobutylene’s effectiveness as an octane booster and its established usage in the industry give it a strong position, mitigating the threat from substitutes to some extent.

Overall, the demand for diisobutylene is closely linked to the dynamics of the automotive industry, regulatory standards, technological advancements, and economic factors influencing fuel consumption patterns globally.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

- Adapting the report to the country/region where you intend to establish your plant.

- Adjusting the manufacturing capacity of the plant according to your needs.

- Customizing machinery suppliers and costs to meet your requirements.

- Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA