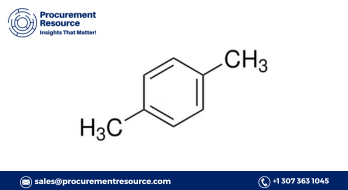

1,4-Dimethylbenzene, also known as p-xylene, is a crucial chemical compound used primarily in the production of polyester fibers, resins, and films. As demand for these products continues to rise, understanding the Production Cost of 1,4-dimethylbenzene becomes essential for manufacturers to maintain competitiveness and profitability. This article aims to analyze the factors influencing the production cost of 1,4-dimethylbenzene and explore strategies for cost optimization.

Factors Influencing Production Cost

- Raw Material Prices: The primary raw material for 1,4-dimethylbenzene production is ortho-xylene, whose price fluctuations directly impact production costs. Changes in ortho-xylene prices due to market demand, supply disruptions, or geopolitical factors can significantly influence the overall production cost.

- Energy Costs: Energy-intensive processes are involved in the production of 1,4-dimethylbenzene, including catalytic reforming and separation techniques. Fluctuations in energy prices, such as natural gas or electricity, can impact production costs and profitability.

- Process Efficiency: The efficiency of production processes plays a crucial role in determining production costs. Optimization of reaction conditions, catalyst selection, and purification techniques can reduce energy consumption and raw material usage, thereby lowering production costs.

- Capital Investment: Initial capital investment in plant infrastructure and equipment contributes to fixed costs, which are amortized over the production lifecycle. Efficient utilization of assets and economies of scale can help spread these costs and reduce the per-unit production cost.

- Regulatory Compliance: Compliance with environmental regulations and safety standards adds additional costs to production. Investments in pollution control technologies, waste management, and employee training contribute to overall production costs but are essential for sustainable operations.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/1-4-dimethylbenzene/request-sample

Strategies for Cost Optimization

- Supply Chain Optimization: Establishing strategic partnerships with reliable suppliers and optimizing logistics can help mitigate raw material price fluctuations and reduce transportation costs.

- Technology Innovation: Investing in research and development to improve production processes, develop novel catalysts, or implement advanced separation techniques can enhance process efficiency and reduce production costs.

- Energy Efficiency Measures: Implementing energy-saving initiatives, such as heat integration, process optimization, and use of renewable energy sources, can lower energy consumption and reduce production costs.

- Continuous Improvement: Adopting a culture of continuous improvement and employee engagement can lead to innovative cost-saving ideas and efficiency gains across all aspects of production.

Risk Management Strategies

Risk management strategies play a vital role in minimizing potential threats and uncertainties that could impact the production cost of 1,4-dimethylbenzene. Here are some key strategies:

- Market Risk Hedging: Utilize derivative instruments such as futures or options contracts to hedge against adverse price movements in raw materials, energy, or finished product prices. This helps stabilize input costs and protect profit margins.

- Diversification of Suppliers and Markets: Reduce dependency on single suppliers or markets by diversifying the supplier base and expanding into multiple geographic regions. This mitigates the risk of supply chain disruptions due to factors such as natural disasters, geopolitical tensions, or regulatory changes.

- Contractual Risk Allocation: Negotiate contracts with suppliers, customers, and service providers that clearly define responsibilities, liabilities, and dispute resolution mechanisms. This ensures clarity and reduces the potential for costly disputes or legal issues.

- Insurance Coverage: Obtain comprehensive insurance coverage, including property insurance, business interruption insurance, and liability insurance, to protect against unexpected events such as equipment breakdowns, accidents, or lawsuits. Regularly review insurance policies to ensure adequate coverage based on evolving risks.

- Contingency Planning: Develop contingency plans and emergency response protocols to address potential disruptions to production operations. This includes scenarios such as supply chain disruptions, equipment failures, or regulatory compliance issues. Regular drills and simulations help ensure readiness to respond effectively to emergencies.

- Compliance and Regulatory Risk Management: Stay updated on relevant regulations and compliance requirements in the industry and proactively address any potential compliance risks. Implement robust systems and procedures for regulatory compliance monitoring, reporting, and auditing to avoid penalties or fines.

- Financial Risk Management: Monitor and manage financial risks such as currency exchange rate fluctuations, interest rate changes, and credit risk. Utilize financial instruments and strategies such as currency hedging, interest rate swaps, and credit risk assessments to mitigate these risks.

- Supply Chain Resilience: Assess the resilience of the supply chain and identify potential vulnerabilities or single points of failure. Implement measures to enhance supply chain resilience, such as inventory optimization, supplier diversification, and alternative sourcing options.

By implementing these risk management strategies, producers of 1,4-dimethylbenzene can enhance their ability to navigate uncertainties and safeguard against potential disruptions, thereby ensuring the stability and profitability of their operations.

Market Demand and Price Fluctuations

Market demand and price fluctuations are significant factors that can influence the production cost of 1,4-dimethylbenzene. Here’s how they impact the production process and strategies to manage them:

- Market Research and Forecasting: Conduct thorough market research and analysis to anticipate shifts in consumer demand and industry trends. Utilize forecasting models and market intelligence to make informed decisions about production levels and pricing strategies.

- Diversification of Product Portfolio: Diversify the product portfolio to reduce reliance on a single product or market segment. Explore opportunities to develop new products or applications for 1,4-dimethylbenzene derivatives to capture additional market segments and mitigate the impact of demand fluctuations.

- Flexible Production Capacity: Maintain flexibility in production capacity to adjust output levels in response to changes in market demand. Implement agile production processes and scalable infrastructure to ramp up or scale down production as needed to optimize resource utilization and minimize costs.

- Long-Term Contracts and Agreements: Secure long-term contracts or agreements with key customers or suppliers to provide stability in pricing and demand visibility. Establish strategic partnerships and collaborations to share market insights and coordinate production planning efforts.

- Risk Hedging Strategies: Utilize risk management tools and financial instruments, such as futures contracts or options, to hedge against price volatility and mitigate the impact of adverse market conditions. Develop risk management policies and protocols to assess and manage exposure to market risks effectively.

- Customer Relationship Management: Build strong relationships with customers and suppliers based on trust, reliability, and responsiveness. Maintain open communication channels to understand their needs and preferences, address concerns promptly, and collaborate on solutions to mitigate market-related risks.

- Continuous Monitoring and Adaptation: Continuously monitor market dynamics, including demand trends, competitor actions, and pricing movements. Stay agile and adaptable to adjust strategies and operations in real-time to capitalize on opportunities and mitigate risks in dynamic market environments.

By implementing these strategies, producers of 1,4-dimethylbenzene can effectively manage market demand fluctuations and price volatility, ensuring resilience and competitiveness in the global marketplace.

Conclusion

The production cost of 1,4-dimethylbenzene is influenced by various factors, including raw material prices, energy costs, process efficiency, capital investment, and regulatory compliance. Manufacturers must continuously monitor these factors and implement strategies for cost optimization to remain competitive in the market. By leveraging supply chain optimization, technology innovation, energy efficiency measures, and continuous improvement initiatives, producers can achieve sustainable cost reductions and ensure long-term profitability in the production of 1,4-dimethylbenzene.

Contact Us

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA